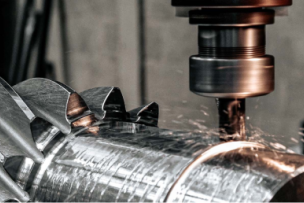

Even a company with decades in the industry will occasionally struggle with its cutting fluid consumption. A large UK-based aerospace components manufacturer that performs milling, turning, and grinding operations experienced this firsthand. Their location houses over 100 machines that work with a range of materials, including aluminum, steel, titanium, and Inconel. Along with achieving performance objectives, they also needed to meet local and internal health, safety, and environmental standards.

THE CHALLENGE

Poor coolant stability resulted in a costly and time-consuming regime of biocide additions to the majority of the machine sumps at their manufacturing site. Without the biocide additions, the coolant would not meet regulatory health, safety, and environmental requirements or internal health and safety standards. The components manufacturer set a coolant life expectation of 18 months as part of the planned maintenance clean-out process, but the biocide was necessary to reach that target.

Additionally, machine operators did not like the existing coolant; it emitted a bad odor.

THE SOLUTION

To deal with this challenge, the components manufacturer actively sought out a product to test in its machines to eliminate the need for additives and improve operator acceptance. That product was TRIM® MicroSol® 590XT, an environmentally-friendly, semisynthetic, microemulsion metalworking fluid.

THE RESULTS

A six-month test run of TRIM MicroSol 590XT proved that no biocide additions were needed to meet the company’s coolant life expectancy standards. Additionally, using TRIM MicroSol 590XT reduced consumption. The top-up strength for its former coolant was 2%, and with TRIM MicroSol 590XT, it was lowered to 1%.

Machine operators also accepted the new coolant enthusiastically. They began asking for TRIM MicroSol 590XT to be put in all of their machines.

The company is currently in a planned conversion process with the possibility of the remaining machines moving to TRIM MicroSol 590XT. They’re also looking at opportunities to supply TRIM products to the remaining companies under their company umbrella.

THE NUMBERS

- Top-up strength halved from 2% to 1%

- Biocide additions no longer needed

- Machine operators requested TRIM MicroSol 590XT in all their machines

Previously Featured on Master Fluid Solutions' Case Studies.

Talk to Us!

Leave a reply

Your email address will not be published. Required fields are marked *