The third and newest grade, the MC5125, represents an expansion in the series since there are only two grades in the older 5000 series of cast-iron inserts, Jewell says.

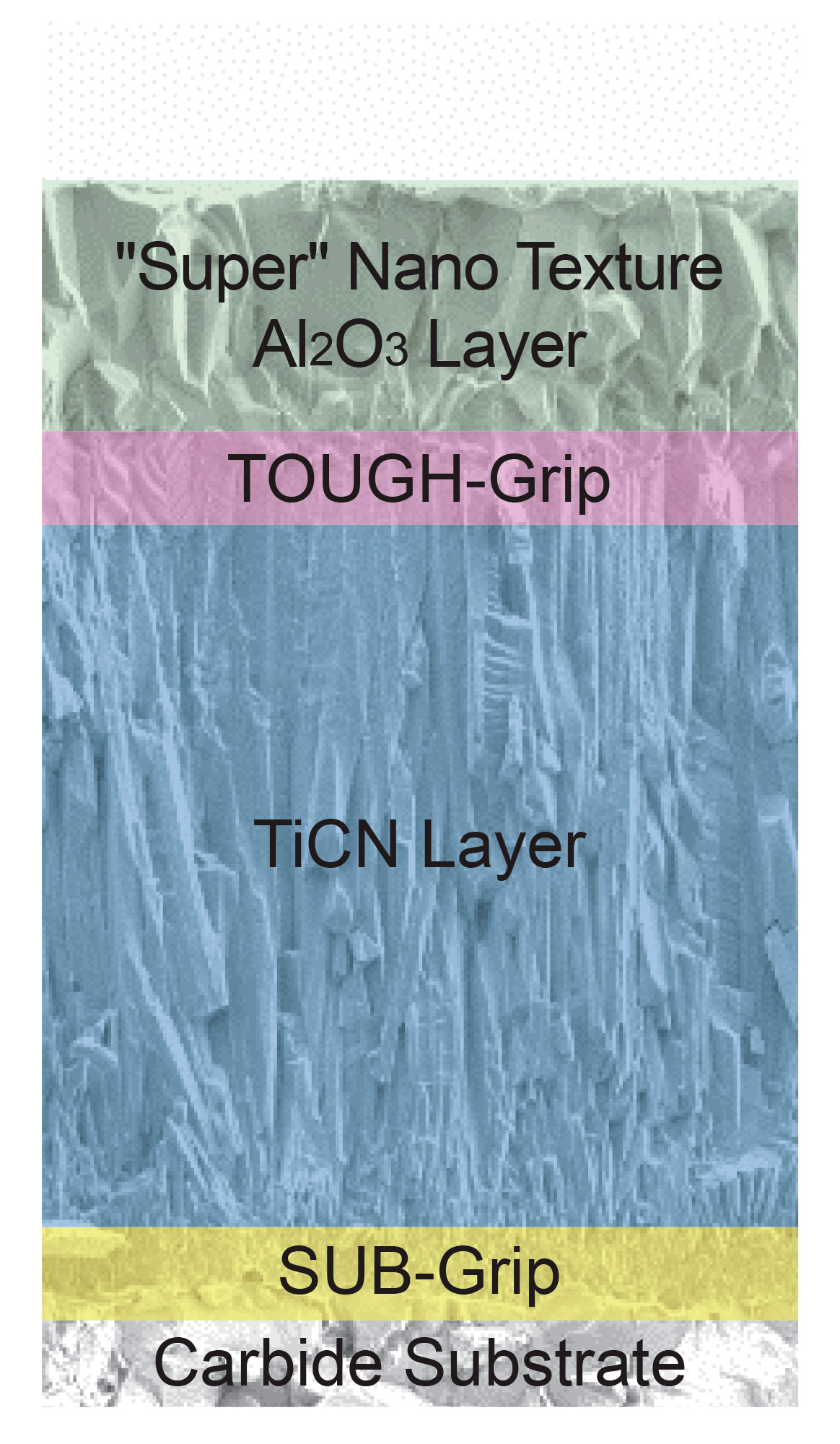

Like the 5115, the 5125 also has four layers including two sub-grip layers, which improve the resistance to delamination. But in addition, those layers have been optimized for interrupted applications, such as machining ductile cast-iron gears, so that you can disperse the impacts in a nonuniform pattern.

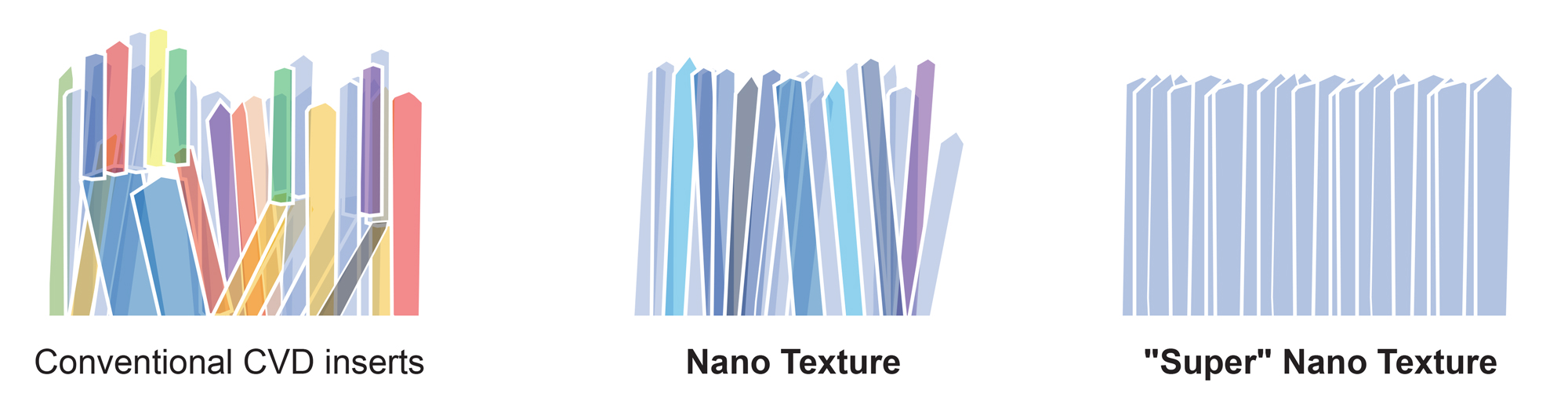

“If we create a pattern where the impact disperses the same each time, then that creates a wear line and the insert can crack much faster,” Jewell explains. “But the Super Nano Texture layer helps prevent that because it disperses those impacts nonuniformly, so it doesn’t create a wear line as quickly.”

Options for Chip-Breakers

The MC5100 series includes a variety of chip-breakers—the features on the top of the inserts that help control and break up chips during machining.

The main breakers for this line are LK, MK and RK, which stand for “light for cast iron,” “medium for cast iron,” and “roughing for cast iron.”

Mitsubishi also offers a flat top chip-breaker, Jewell says, “because in cast iron, you’re trying to run fast, and a flat top gives you the most edge strength since the thickness of the insert is the same on the corner as it is in the center.”

Another innovation from Mitsubishi involves a small change to the mounting of its negative inserts. “We increased the face contact area between the insert and the screw from the traditional 9 square millimeters to 31 square millimeters,” Jewell says. “That change in the breaker design allows the insert to sit flatter on the holder and be tightened down more securely. As a result, we get more clamping force, and the insert stays firmly in place without shifting.”

Jewell says Mitsubishi is in the process of phasing out the older 5000 series cast-iron grades and replacing them completely with the new 5100 series. By September 2025, all previous 5000 series grades will be discontinued, and manufacturers will need to transition to the newer high-performance 5100 series inserts.

What’s your biggest challenge when machining cast-iron components? Tell us in the comments below.

_0.jpg)

Talk to Us!

Leave a reply

Your email address will not be published. Required fields are marked *