Mobile inventory management tools help workers be efficient in their tasks and allow wide visibility of production environments during day-to-day operations.

We are all familiar with the basic measurements taken by a height gage, but many of today's new instruments can perform with near coordinate measuring machine (CMM) capabilities.

What’s going on in today’s metrology—especially in light of Industry 4.0 and the future? As specifications for parts become more and more precise, so too does their measurement.

Reaching the next level in productivity is not about the incorporation of individual products, but rather the integration of complete systems that work together to help manufacturers realize greater efficiencies. At Micro-Mechanics, they have done just that to increase productivity, profitability and a global competitive advantage.

When an engineer includes a surface finish spec on a print, the intent is not just to make the part look good. It affects how a part will fit, wear, reflect light, transmit heat, distribute lubrication and accept coatings. The finish should be determined by the part’s function, without wasting time and effort on a higher quality finish than is necessary.

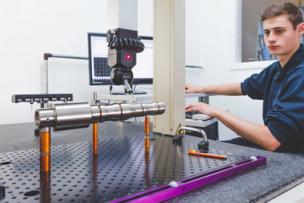

When standard devices can’t provide expected results, a better solution is to custom design a gage to suit the specific application.

Oils, pastes, gels and emulsions – traditional machining fluids come in many forms. But they all have something in common in that they pose a risk to worker health and the environment. Steve Skerlos of Seco Tools’ new partner Fusion Coolant Systems has come up with a sound alternative.

Take full advantage of your machine tool’s milling power for increased productivity with Seco’s new Double QuattromillTM 22 face mill cutter for roughing and semi finishing. Achieve large depth-of-cut capability and do so cost-effectively with eight multi-edge insert cutting edges.

No longer just the stuff of imagination, artiicial intelligence (AI) is now having a major impact on the way we live our lives. In the manufacturing and production sector, its influence can be seen in the form of increasingly smart robots.

By now Safe-Lock™ has become a de-facto standard in the area of tool holding for milling operations. Within the last 10 years, since the introduction of the Safe-Lock™ system, it has been confirmed over and over that this method of clamping the tool is often clearly superior to conventional Milling Chucks and Weldon shanked tool holders.