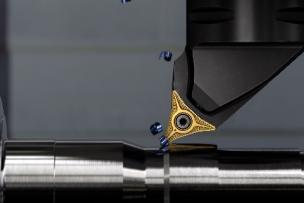

New indexable inserts from Walter deliver superior thread turning in tight spaces.

Productivity is top of mind for many manufacturers and Lenox has responded with an alternative to traditional band saws. CIRCTECH, also known as thin kerf or industrial circular sawing, is a growing market and many band saw customers are now switching to this technology due to its many cutting benefits, such as fast cutting rates, long blade life, high accuracy and surface finish. Customers are also reporting a lower total cost of operations with a reduction in scrap, less noise and less saw maintenance over band saws.

For more than 50 years, coordinate measuring machines (CMMs) have been improving measurement productivity and quality. The power of CMMs has made many complex inspection tasks seem almost trivial. With this much measurement capability, is it possible operators are taking their CMMs for granted?

There are many times when a machinist, while cutting a few parts or getting ready for an initial run, needs to check a few parts or a few critical features.

At the ribbon-cutting to kick off IMTS 2018, the president of AMT emphasizes that the acceleration of technology has a more direct and immersive role in manufacturing systems than ever before.

As part tolerances tighten, both form and surface finish have a bigger influence on the size and function of the product. With pressures on manufacturing to be more productive, it’s becoming more important to measure surface finish right at the point of manufacture—often by the same machinist who is manufacturing the part.

Whether tough materials, bad coolant, poor workholding, technology or process—there’s always room for metalworking improvement.

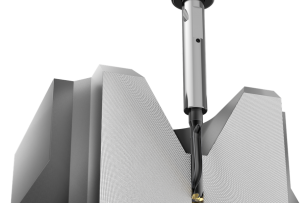

Reaching deep inside a workpiece to drill holes can be a real bear. You’ve tried just about every solution you can think of and wonder if there’s a better way. Kennametal thinks so. Find out more about their new hydraulic chuck extension that meets the challenges you face while also increasing flexibility and reducing costs.

Forward and back turning is nothing new; however, PrimeTurning offers the first and only tool on the market to combine all directional turning in one tool.

Challenging machining places high demands on insert grades for turning heat resistant super alloys (HRSAs) and titanium.