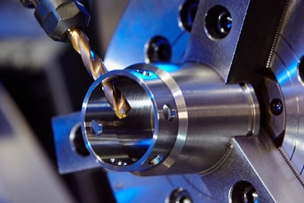

New drills from Guhring, Kennametal and OSG are designed to tame some of holemaking’s toughest challenges. Here’s what you need to know about them.

In this episode of MSC's Tooling Up, host Toni Neary welcomes Sadler Kleve, National Account Representative for Osborn, to discuss the latest advancements in the deburring process.

A new steel turning insert grade from Sandvik Coromant helps an Ontario automotive supplier improve its machining process.

Aluminum is manufacturing’s preferred metal for products from cars to rockets, medical implants and electronic connectors but improper milling can leave a poor surface finish and damage tools. Here’s how to avoid those problems.

Cutting fluids are more than just an operational necessity in machining — they play a critical yet often unsung role in the overall effectiveness of the production process.

One of the most fundamental aspects of metrology, part interchangeability and adherence to measuring standards is tolerancing. Here’s what you need to know to get started.

MSC’s Accupro® ST Series, a 3-piece milling assembly that is sold pre-set, pre-balanced and ready to use, leverages the science of machining dynamics to highlight which specific operating parameters will maximize productivity. It helps users address three critical business priorities: competitiveness, revenue growth through capacity gains and overcoming the widening gap in manufacturing skills.

Throughout history, manufacturers have sought ways to make their machining processes more efficient and cost-effective.

In this episode of MSC's Tooling Up, Toni Neary sits down with Brandon Hull, Vice President of Product Management and Business Development at Guhring Inc., to discuss the innovative Diver and Micro Diver End Mills.

High-quality metalworking fluids like HyperSol 888NXT from Master Fluid Solutions deliver more than heat resistance and lubricity: They can help users prolong tool life, curb production time and even control unpleasant machine shop smells.