The MC5100 series of inserts from Mitsubishi Materials represents the next generation of high-performance turning grades for cast iron. The inserts are engineered to run faster, more consistently and more predictably in demanding high-volume industrial environments.

Modern workholding solutions such as modular vises, fixture plates and pneumatic systems are helping machine shops reduce setup time, improve precision and adapt more easily to high-mix, low-volume production.

Many manufacturers are shifting away from traditional pneumatic and electric tools to modern tools powered by lithium-ion batteries, which improve safety, reduce fatigue and enhance portability on jobsites.

MSC’s new Accupro® Indexables line includes more than 650 milling, turning and grooving tools, combining high-performance cutting with the cost-effectiveness of reusable holders.

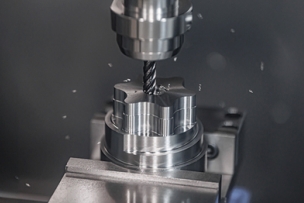

Collet chucks and collets are essential to CNC machining, yet they’re often overlooked. Worn collets can cause tool runout, poor finishes, and even spindle damage, leading to costly downtime. Regular inspection and replacement are key to maintaining performance and avoiding unnecessary expense.

Mitutoyo’s expanded line of laser scanners provides manufacturers with deep insights into production processes—enabling smarter, more efficient manufacturing across a wide range of industries.

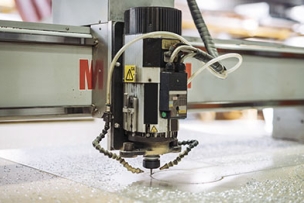

Machining composites such as carbon and glass fiber are challenging due to abrasion, delamination and other issues. Diamond-coated tools with specialized geometries improve cut quality, extend tool life, and help manufacturers reduce overall machining costs.

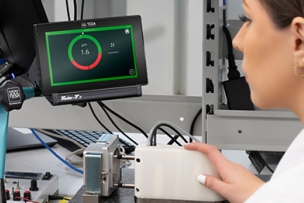

TESA Technology’s Twin-T20 remote display unit simplifies precision measurement with user-friendly, color-coded feedback, helping manufacturers boost quality and efficiency without requiring specialized training.

Reshoring is gaining momentum as tariffs and supply chain risks push U.S. manufacturers to localize. But high build costs, labor shortages and global input reliance demand smarter strategies.

In milling applications, the phrase “more is better” often—but not always—applies. Here’s what you need to know.