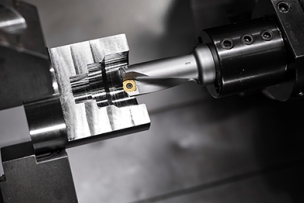

Regular, properly performed calibration is crucial to meeting customers’ specifications for manufactured and machined parts. Here’s what you need to know.

For machine shops tackling a variety of holemaking jobs in workpieces of all shapes, sizes and materials, versatile drills are crucial.

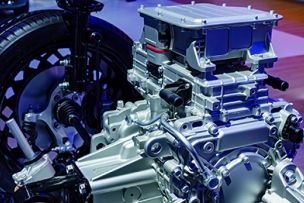

Move over mild steel. Get lost, gray cast iron. Thanks to the surge in electric vehicle sales, machinists can look forward to tackling tougher, stronger alternatives.

Work hardening, built-up-edge, chipping and downright destruction of cutting tools are among the challenges involved in machining Inconel, a common but misunderstood alloy. Here are some tips on how to avoid them.

Sandvik Coromant is adapting and expanding its metalworking tool lineup to meet the needs of a rapidly growing electric vehicle market.

Cutting fluids are usually underappreciated and often abused. Here are 19-plus hacks to keep them fresh, effective and in the machine longer.

Drilling grows more difficult as hole depths increase, with poor chip evacuation, drill breakage, and undesirable hole quality being the primary causes of failure. Here’s some advice for improving tool life and making drilled holes run true.

To stay competitive in tomorrow’s workplace, learning how to operate, set up and program robots is essential. Here’s how to get the training you need.

Osborn’s Honey Badger Double Stringer Bead Brush essentially melds two brushes into a single wheel, enabling it to clean both sides of a weld at the same time and providing twice the life span and cutting force of previous models.

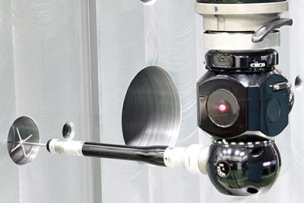

Many machine shops, especially those that have adopted robotic equipment tending, have turned to automated measurement technology as the surest way to avoid scrapping workpieces.