Among the features that distinguish Acu-Rite’s digital readouts and CNC controls from the rest of the market are durability, user-friendly design and a comprehensive approach to its product lineup.

Offline simulation and toolpath optimization help to improve productivity, streamline setups and avoid expensive crashes. Four experts explain how.

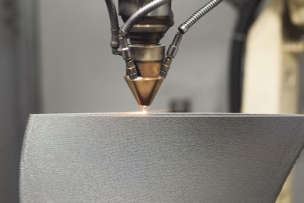

Metal 3D printing has become a viable option for more manufacturers, thanks to improvements in mechanics and materials and new approaches to design and production. Here are the latest tools and techniques.

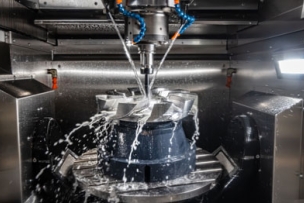

To optimize your machine shop’s performance, consider the strategic and technical needs of each job before jumping straight to production, says a Seco Tools adviser.

Digital supply chains can help metalworking businesses fight back against the crunch of delayed raw material deliveries, labor shortages and spiking inflation.

Combining Kennametal’s new FBX drills, Harvey Ultra 8X indexable helical end mills and Harvi III solid carbide end mills can give machine shops the flexibility to power past older or less powerful equipment or tight workspaces.

Most machine shops need outside expertise to overcome obstacles to modernization, from insufficient institutional know-how to a shortage of cash for equipment upgrades. The Manufacturing Extension Partnership can help.

MIG welding is usually the first type of welding that people learn. Follow these five tips from industry experts to lay down the best bead possible.