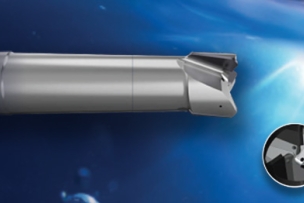

Guhring introduces the PCD Diver, a cutting-edge end mill engineered to excel in aluminum machining applications.

MSC’s new Accupro® Indexables line includes more than 650 milling, turning and grooving tools, combining high-performance cutting with the cost-effectiveness of reusable holders.

The M610 from Sandvik Coromant is a stand-alone product for finishing milling of bi-metal materials (aluminum and GCI).

Kennametal is responding to higher demand for precision machining solutions from the aerospace and medical device industries with an expanding lineup of cutting tools such as micro-drills and Swiss-type turning inserts. Here’s what you need to know.

Buying low-quality metalworking fluid may cost more money than it saves in the long term; improper maintenance may worsen the problem. Here’s what you need to know.

As the use of heat-resistant superalloys (HRSA) expands across industries, manufacturers need a reliable milling solution for these tough-to-machine materials.

Aluminum is manufacturing’s preferred metal for products from cars to rockets, medical implants and electronic connectors but improper milling can leave a poor surface finish and damage tools. Here’s how to avoid those problems.

MSC’s Accupro® ST Series, a 3-piece milling assembly that is sold pre-set, pre-balanced and ready to use, leverages the science of machining dynamics to highlight which specific operating parameters will maximize productivity. It helps users address three critical business priorities: competitiveness, revenue growth through capacity gains and overcoming the widening gap in manufacturing skills.

In this episode of MSC's Tooling Up, Toni Neary is joined by Senior Director of Metalworking Sales and Innovation Jamie Goettler of Accupro for a discussion on the new Accupro ST series.

The FHFP series of end mills from the TuffCut HF family, M.A. Ford’s first foray into true high-feed cutting geometries, can tackle jobs in a diverse range of materials and industry sectors. Here’s what you need to know.

copy 3.jpg?itok=jDQ0Lywg)