Three cutting tool experts explain why machining times are often longer than they should be and what you should do about it

3D contour milling is used heavily in industries that create complex three-dimensional parts such as the aerospace, medical, and mold & die sectors.

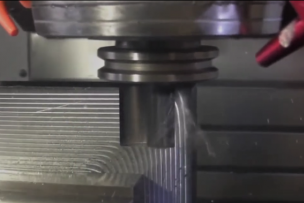

For manufacturers willing to make the investment, circle segment cutting can reduce cycle times and increase tool life of certain CNC jobs. Here’s what you need to know.

The KCFM 45 fine-finishing face mill from Kennametal provides high-precision pocket seats, exceeding highest surface requirements.

Accupro's milling tools are ideal for removing stock, tackling detailed work pieces, and refining previous operations.

In peel milling, also known as slicing, the cutting speed can be higher when compared with traditional milling methods.

In this episode of MSC's Tooling Up, Eddie Sauders Jr., MSC Expert Host, is joined by Chris Dixon, Applications Engineer at Kyocera SGS Precision Tools, Inc. for a real-time discussion and demonstration of the Series 77 H-Carb 7 Flute High-Efficiency End Mills.

KYOCERA SGS highlights five advantages of trochoidal milling in this video.

The new A Brand® AE-VMS from OSG Tools is an advanced performance anti-vibration carbide end mill designed for high-efficiency milling.

End mills featuring a cutting edge that is reminiscent of a barrel profile were introduced 25 years ago. However, advances in 5-axis machining and in CAM systems have significantly expanded the boundaries of barrel end mill applications.