Among the features that distinguish Acu-Rite’s digital readouts and CNC controls from the rest of the market are durability, user-friendly design and a comprehensive approach to its product lineup.

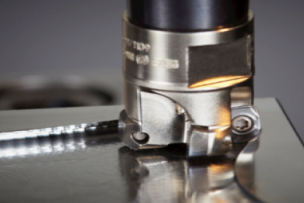

In selecting 90°milling cutters, there are several factors to be examined such as the material to be machined, the removal of stock, required accuracy, surface finish, stability, and the characteristics of the machine tool in use.

To optimize your machine shop’s performance, consider the strategic and technical needs of each job before jumping straight to production, says a Seco Tools adviser.

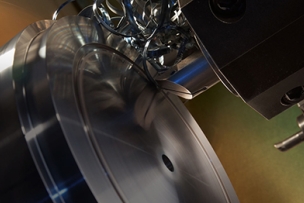

Seco Tools offers some helpful tips to milling hardened tool steels that present unique challenges.

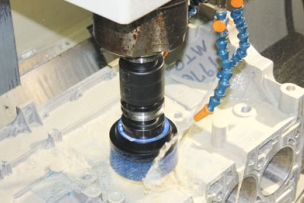

Some aluminum alloys pose chip-control problems that can spell big trouble for lathe productivity. Here are steps you can take to get past that obstacle and on with the job.

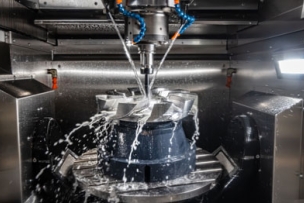

Combining Kennametal’s new FBX drills, Harvey Ultra 8X indexable helical end mills and Harvi III solid carbide end mills can give machine shops the flexibility to power past older or less powerful equipment or tight workspaces.

Thread milling and tapping have distinct advantages and disadvantages, and knowing when to use one over the other can make or break a job. Two experts compare the two threading methods.

Premium toolmaker OSG addresses the tradeoff between tool life and productivity, a thorny obstacle for machine shops, with its A Brand AE-N end mills that improve both.

E-manufacturers say once-revolutionary 3D printing complements CNC machining and other more traditional manufacturing processes, making it just another (albeit very powerful) tool in their toolboxes.

Your workers may be plenty busy deburring by hand, but your business could be more profitable if you switched to a mechanical process using the right brush set to the right parameters. The experts at Osborn explain.