Learn better ways to hold your tap than just a tension-compression holder where you don’t have to worry about over-cutting threads in this short video.

Learn how to install, remove and select the right threading insert for you.

For machinists drilling holes into oblique or curved surfaces, Guhring’s RT 100 FB can replace as many as three tool changes and setups required with other tools.

An artificial lift solution provider for the oil and gas industry turned to OSG to resolve a threading issue on its production of flanges and blocks.

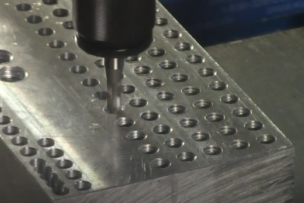

For years, machinists avoided thread milling when possible because it required much longer setup times than tapping. With a trio of thread-milling innovations, OSG is rewriting that playbook.

Thread milling and tapping have distinct advantages and disadvantages, and knowing when to use one over the other can make or break a job. Two experts compare the two threading methods.

Walter's universal TC117 blind-hole and TC217 through-hole taps tackle a wide range of materials.

Advances in technology and metallurgy have facilitated the development of indexable inserts that are far more advanced than their predecessors, and complicated shapes have replaced the simple forms that characterized inserts in the past.