Seco has introduced two new chip splitter milling inserts that lower the stress on both the machine and cutting tool for improved milling process stability.

The right type of contact between the edge and material at the entry and the exit of a cut must be considered for successful milling.

LOGIQ 4 FEED is ISCAR’s latest high-feed milling family of tools/inserts designed to increase productivity of rough milling applications.

OSG introduces the HY-PRO® Carb VGM3-AL end mill for high-speed machining in aluminum and nonferrous materials.

Machine shops working on medical components grapple with challenges from short turnaround times to low-volume production runs and difficult materials. Kennametal’s range of specialized cutting tools help them deliver workpieces on time and within specifications.

When it comes to indexable milling, one of the main decisions is choosing a lead angle.

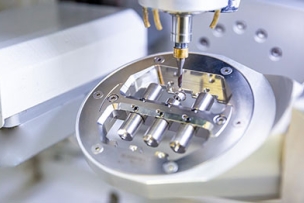

A HAIMER Microset presetter offers benefits from a reduction in setup time of as much as 70 percent to higher productivity, improved workpiece accuracy and longer tool life.

The strength and stiffness that make titanium ideal for aviation equipment and human joint replacements also make it tough for machinists to cut and shape. Here’s what you need to know to work successfully with this widely used metal.

While titanium offers many benefits, such as excellent strength-to-weight ratio and corrosion resistance, it is also notoriously difficult to machine. Here, you’ll discover 10 tips for machining titanium when milling.

Shortened tool life, poor surface finish and built-up edge are common challenges when machining cobalt alloys. These tips can help you overcome them.

_edited.jpg?itok=rc-V2Jwz)