Whether you’re using wheels, disks or paper and pads, abrasives carry a variety of safety hazards. Here’s how to protect your employees.

Supply chain disruptions like the bridge collapse that blocked the Port of Baltimore in early 2024 are heightening interest in reshoring American manufacturing.

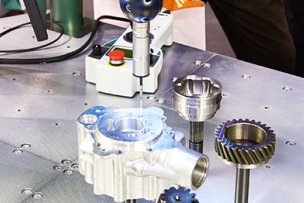

Coordinate measuring machines are not only growing more capable—seemingly by the day—they’re also becoming an indispensable tool on the production floor. Here’s what you need to know.

Machine shops working on medical components grapple with challenges from short turnaround times to low-volume production runs and difficult materials. Kennametal’s range of specialized cutting tools help them deliver workpieces on time and within specifications.

The rise of Industry 4.0 and the advent of artificial intelligence are overhauling the skillsets needed in manufacturing jobs. Here’s how educators and businesses are taking on the challenge.

Recycling worn carbide cutting tools not only benefits the environment, it’s also good for your pocketbook. Here’s what you need to know.

Machine shops grappling with an array of economic challenges are getting help from aftermarket services including maintenance and repair offered by their equipment suppliers.

A HAIMER Microset presetter offers benefits from a reduction in setup time of as much as 70 percent to higher productivity, improved workpiece accuracy and longer tool life.

Artificial intelligence has the capability to analyze data from a smart factory’s machinery to spot unfavorable trends, look for continuous improvement opportunities and alert maintenance staff of impending breakdowns. Here’s what you need to know.

While rigid honing can remove relatively large amounts of metal and improve hole straightness and roundness, flexible hones “follow” the existing bore and are meant for finishing and deburring operations only. Here’s what you need to know about each.

_edited.jpg?itok=rc-V2Jwz)