Working with sheet metal can be hazardous to hands, arms and eyes. Protect your workers by understanding the regulations and taking precautions.

Kennametal is responding to higher demand for precision machining solutions from the aerospace and medical device industries with an expanding lineup of cutting tools such as micro-drills and Swiss-type turning inserts. Here’s what you need to know.

Buying low-quality metalworking fluid may cost more money than it saves in the long term; improper maintenance may worsen the problem. Here’s what you need to know.

MSC does far more than sell tools and parts. Find out how its team of experienced metalworking specialists—and services from custom parts design to measurement tool calibration and fluid maintenance—deliver added value at the spindle.

Lenox is introducing fee-based inspection and maintenance services for bandsaw operators, helping them extend tool life and avoid costly breakdowns.

Keith Ferguson, DEI Talent Manager at MSC, met with students at our 2024 MFG Day event, and shares his take on the future of the manufacturing workforce.

Even though medical manufacturers continue to machine the lion’s share of all medical implants, additive manufacturing brings special capabilities to the table that CNC machinery will never mimic.

Manufacturers unsure what imports might be subject to new tariffs from the Trump administration are making contingency plans to curb potential fallout.

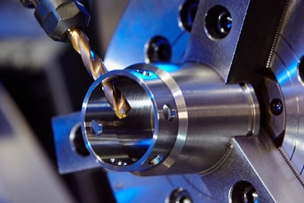

New drills from Guhring, Kennametal and OSG are designed to tame some of holemaking’s toughest challenges. Here’s what you need to know about them.

Aluminum is manufacturing’s preferred metal for products from cars to rockets, medical implants and electronic connectors but improper milling can leave a poor surface finish and damage tools. Here’s how to avoid those problems.

copy 3.jpg?itok=jDQ0Lywg)