Castrol SmartControl measures metalworking fluid conditions from pH levels to concentration and temperature to help customers achieve peak cutting tool performance.

For machinists drilling holes into oblique or curved surfaces, Guhring’s RT 100 FB can replace as many as three tool changes and setups required with other tools.

There’s more to choosing the best end mill than its price tag and availability.

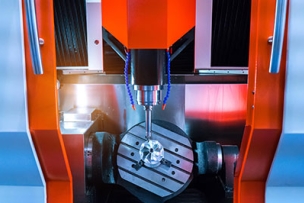

The metals used in making components of high-tech equipment get tougher every year. These tips on maximizing superabrasives can help.

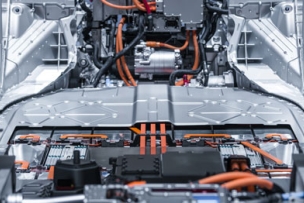

Some parts of electric vehicle production require a different toolbox than the building of their gasoline-powered predecessors. Kennametal has tools for all of them—including custom models created with 3D printing technology.

Working with tungsten is never easy, but these tips can help machinists complete a workpiece successfully.

Here are seven steps machine shops and metalworking businesses can take to reduce the risk of costly stockouts.

How has your business tried to counter spiking inflation?

ITW Pro Brands delivers products that buoy its customers’ bottom lines by focusing on their pain points and developing solutions.

A move by American manufacturers to bring more of their machining work in-house is increasing the need for manual milling machines, often used in tool cribs, repair shops and prototyping departments. Here’s what you need to know about tramming the machines for optimal operation.