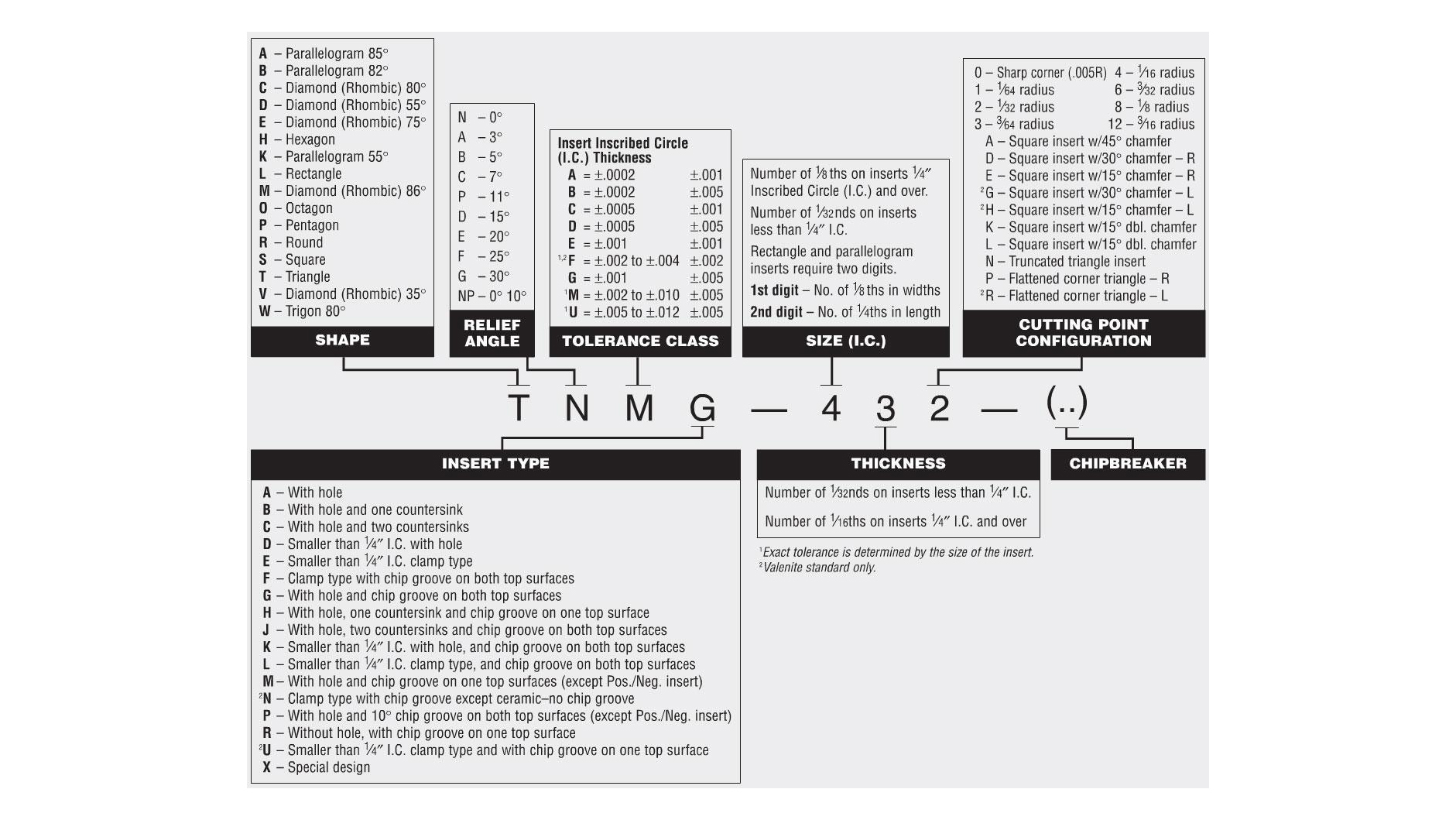

Basics of Chip Breaker Inserts: References and Nomenclature

Different industrial applications require specific chip breakers or indexable inserts for material removal. Using a carbide insert chart as a cross-reference helps users understand the function of each breaker or insert for their specific task.

A chip breaker insert breaks large metal chips into smaller, more manageable pieces, improving workplace safety and reducing chip buildup. It also enhances surface finish by promoting smoother, more consistent cuts, while minimizing heat and friction to extend tool life.

What is an Indexable Insert?

Indexable inserts, typically made from durable materials like tungsten carbide, offer a replaceable cutting edge for milling and drilling operations. They maintain hardness and wear resistance at high speeds, extending tool life and boosting productivity, similar to chip breakers.

Carbide Insert Chart and Cross References

Operation | Kennametal | Sandvik | Seco | Walter-Valenite | Iscar | Hertel |

Fine Finishing | FF | PF | MF2 | C5, F2 | RF, FF | BF,HF, BFM |

Fine Finishing | UF | UF, QF | FF1 | PS5 | SF, SM | HF, CFM |

Finishing | LF | PF | F1 | F5, PF2, PF4 | NF | AF, AM, LF, HMF |

Finishing | LF | MF,-23 | MF1 | F5, NF3, NF4 | TF | AF, AM, LF, HMF |

Finishing | FP | MF1 | F5 | PP | F, HF, HMF | |

Finishing | FN | PF | MF2 | PF4 | PP | F, HMF, AMF |

Finishing | MP-K | MF5 | M4, M5 | TF, GN | F | |

Medium Machining | CT | |||||

Medium Machining | MP | MF | MF3 | M5 | TF | HMF, HM, M2 |

Medium Machining | MS | M1 | M2, PM2 | VL | L3, HL1, L4, M1 | |

Medium Machining | MN | PM | M2 | M3 | GN | HM, M2 |

Medium Machining | MN | PM | M3 | PM4, PM5, NM9 | TNM | HM, M2 |

Medium Machining | MN | QM | M5 | NM4, NM5, NM6 | NR, TNM | HM, M2 |

Medium Machining | P | 2C, 73 | MR3 | F5, C5 | GN | HM, L5, L6, M1, |

Medium Machining | GP | -23 | M1 | M2, F5 | PP | EMU, ENZ 3J MS PP, TH |

Medium Machining | UP | M3 | 55, | M5 GN | M2 EMU, ENZ | MF5 |

Roughing | RP | QM | MR3 | NR4 | NP | HM, HRM, R |

Roughing | RP | QM | MR4 | NR4 | RP | HRM, R |

Roughing | UN | PR | M5,MR7 | R3 | TNM | HR, HMR, HRM, HRR, R |

Roughing | RN | MR | MR5 | R3 | NR | HR, HMR, HRM, HRR, R |

Roughing | RN | PR | MR4 | R3 | NR | HR, HMR, HRM, HRR, R |

Heavy Roughing (Single Sided) | RH | HR | R8 | NR4 | RP | R10 |

Heavy Roughing (Single Sided) | RH | HR | RR9 | RP4 | RP | R25,R25Z |

Heavy Roughing (Single Sided) | RM | PR | R4 | RP4 | -12 | Q8 |

Heavy Roughing (Single Sided) | RM | PR | R6 | NM | R75,R75Z | |

Heavy Roughing (Single Sided) | RM | HR | R7 | NM |

Operation | Sumitomo | Stellram | Mitsubishi | Tungaloy | Interstate |

Fine Finishing | ESU | 1A, 62 | SH | TS, TSF | IF, P |

Fine Finishing | ESU, ESX | -62 | FV, FW | 1, TSF | |

Finishing | ESU, ESP, ESX | -62 | FV,FS MQ | PS | 2C |

Finishing | EGU, ESX, EUX | 3F | SH | TM | |

Finishing | EGU, ENK | 2B | SH | ||

Finishing | EGU, ESU, ESX | 1A | SA | TS | |

Finishing | EGU, EUX, ENK | 3J | MS, MV | ||

Medium Machining | 44 | IMF | |||

Medium Machining | EUX, EGU, EUP | 1A | MS, SA | SS | KC |

Medium Machining | EUP | CM | HF | ||

Medium Machining | EGE, EUP. EUX | 2N | MS | CM, TM | MM |

Medium Machining | EGU, EMU, ENG | 2N | MA | TM | IMR |

Medium Machining | EGU, EMU, ENG | 4T | MA | TH | |

Medium Machining | ESE, EGU, EMU, ENG, ENZ | 2C, 73 | MP | SA | |

Medium Machining | |||||

Medium Machining | GJ, MV | TH | |||

Roughing | EMU, EGE, ENZ | 2N | MH | TR | IR, 55 |

Roughing | EMX, ENZ | 4M | MH | TH | |

Roughing | ENZ, EMU | 3M | GH | TU | |

Roughing | EMU, EGE | 5V | MH | SS | |

Roughing | EMX | 5V | GH | TU | |

Heavy Roughing (Single Sided) | EHG | 4M | HV | TR | |

Heavy Roughing (Single Sided) | ENP | 4M | HV | TR | |

Heavy Roughing (Single Sided) | EHG | 5V | HA | TU | |

Heavy Roughing (Single Sided) | ENP | 4M | HA | -65 | |

Heavy Roughing (Single Sided) | EHP | 4M | HV | -65 |