What Is the Goal of 5S?

5S is a Lean method intended to implement order in the workplace.

The goal of 5S is to improve efficiency by eliminating various wastes, including the waste of motion and time spent looking for tools, materials or information.

Other benefits include improved safety and morale due to a more effective work environment.

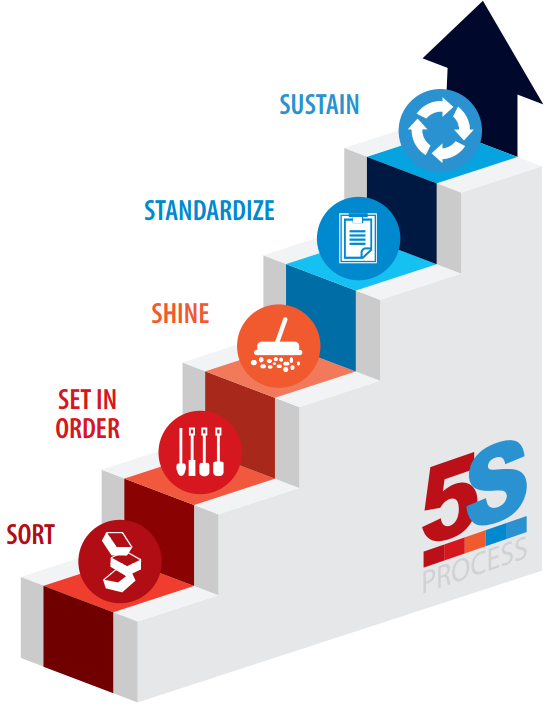

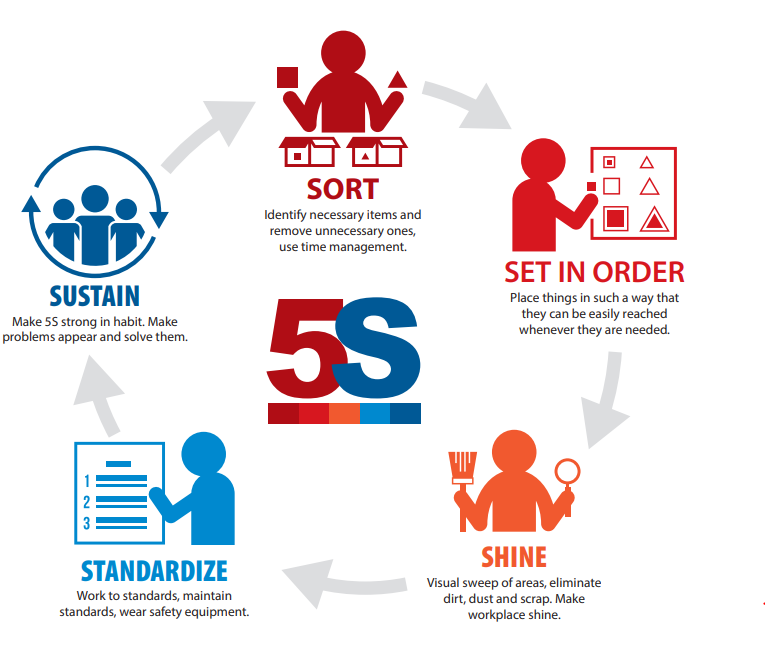

What Is the 5S Process?

SORT

Purge and organize work area.

SET IN ORDER

Understand where items belong to be easily accessible when needed.

SHINE

Clean work area to be free of dirt and clutter.

STANDARDIZE

Document and enforce/reward successful 5S behaviors.

SUSTAIN

Continuously audit and improve process.

Follow every step with Safety!

Download AccuformNMC's recent 5S Visual Solutions Catalog to browse an array of products to help you implement 5S in your workplace.

Why Use 5S?

Remove waste from the workplace.

Provide an environment where continuous improvement is encouraged and embraced.

Create a culture of discipline.

Improve safety.

Improve quality.

The 8 Lean Manufacturing Wastes — 5S Addresses Downtime

Defects

Over-production

Waiting

Non-utilized people

Transportation

Inventory in excess

Motion

Extra processing

1) SORT — Decide What Is Needed

Definition

Why?

Things to Remember

Start in one area, then sort through everything.

Discuss use of items with all persons involved.

Use appropriate decontamination, environmental and safety procedures.

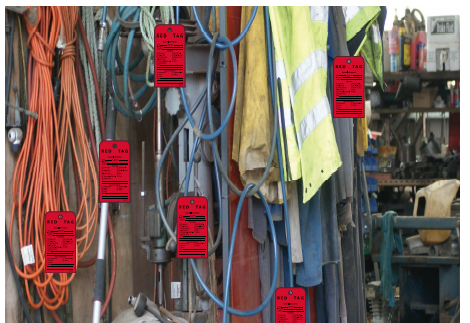

Items that cannot be removed immediately should be tagged for later removal to a red tag holding area.

If necessary, use movers and riggers.

What Is a Red Tag Holding Area?

How to Use the Red Tag Method:

Place items with red tags from sorted areas into the Red Tag holding area.

Keep items highly visible.

Clearly label items.

Assign a Red Tag Manager.

Document rules for:

– Placing items in Red Tag area

– Removal of items

– Disposition of items

2) SET IN ORDER — Arranging Necessary Items

Definition

Why?

Visually show what is required or is out of place.

Efficiently find items and documents (silhouettes/labels).

Save time by not having to search for items.

Travel shorter distances.

Things to Remember

Things used together should be kept together.

Use labels, tape, floor markings, signs, and shadow outlines.

Shareable items are kept at a central location (eliminates excess).

A place for everything and everything in its place.

3) SHINE — Cleaning the Workplace

Definition

Why?

A clean workplace indicates a quality product and process.

Dust and dirt cause product contamination and potential health hazards.

A clean workplace helps identify abnormal conditions.

Things to Remember

“Everything in its place” frees up time for cleaning.

Use an office or facility layout as a visual aid to identify individual responsibilities for cleaning. This eliminates "no man’s land."

Cleaning the work area removes the "grime" of the day to start fresh for success tomorrow.

4) STANDARDIZE — Creating Consistency

Definition

Why?

Maintain the workplace at a level that uncovers problems and makes them obvious.

Sustain sorting, storage and shining activities every day.

Continuously improve your office or facility by continuous assessment and action.

Things to Remember

5) SUSTAIN — Maintaining the 5S

Definition

Why?

Build 5S into our everyday process.

Allow the 5S process time to flourish.

Create opportunities for workplace and production improvement.

Things to Remember

Develop schedules and checklists.

Good habits are hard to establish.

Commitment and discipline toward housekeeping are essential first steps toward being world class.

5S Cheat Sheet