Selecting the Right Absorbent and Chemical Application Guide

Brady SPC details the steps to choosing the correct sorbent for your application.

Brady SPC details the steps to choosing the correct sorbent for your application.

Know What You're Absorbing.

Identify Your Application.

Select Absorbent Features.

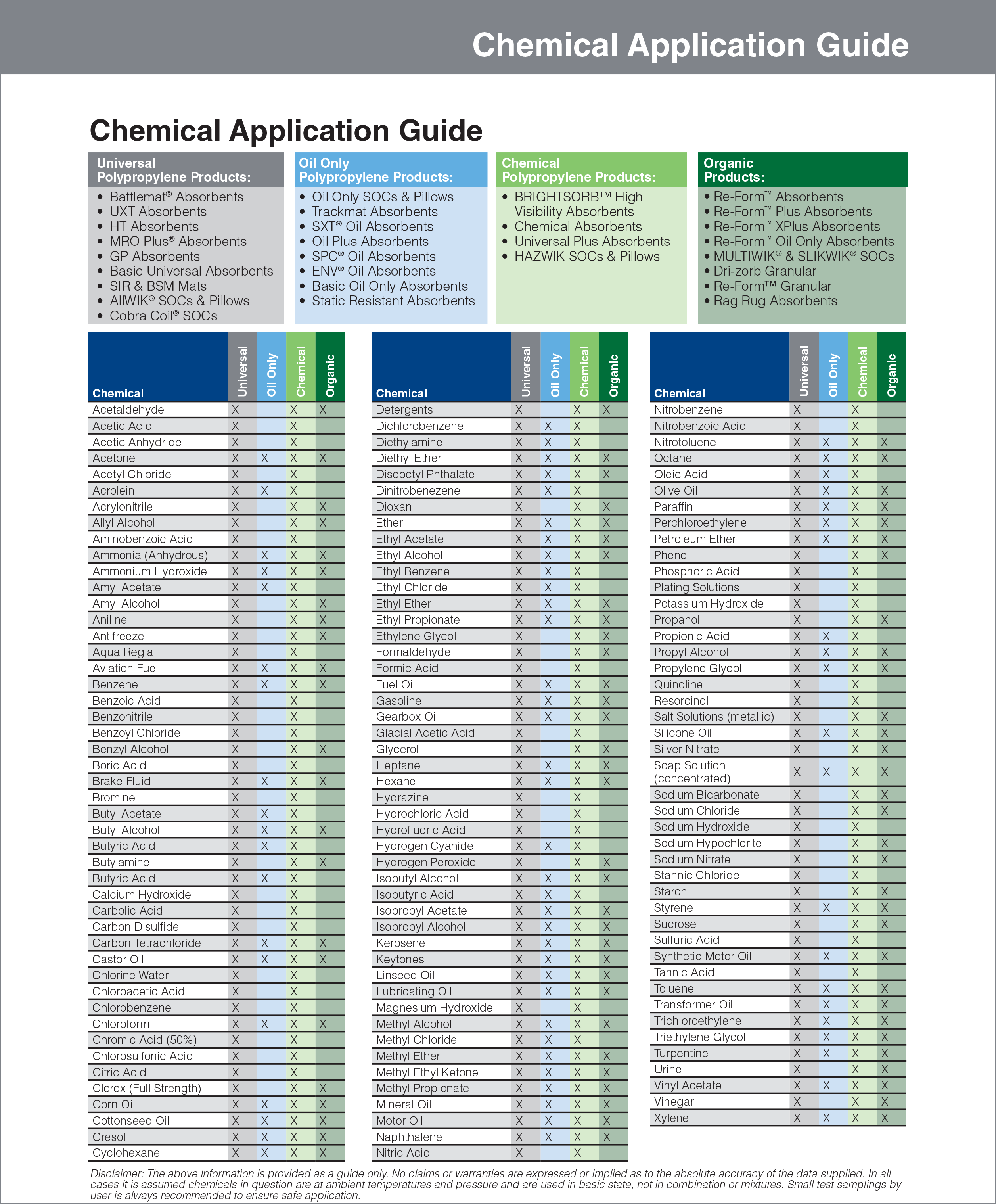

Chemical Application Reference Guide.

Water- or Oil-Based Fluids SPC Recommends: Universal Absorbents

Use around machinery, under leaky pipes, in messy traffic areas or for general maintenance projects. Re-Form™ universal absorbents made of recycled materials offer an environmentally friendly solution.

Coolants

Solvents

Gasoline

Kerosene

Vegetable oil

Latex paint

Oil-Based Fluids Outdoors/Water Repelling SPC Recommends: Oil Only Absorbents

Specialized for oil and other petroleum-based spills including paints and non-water soluble chemicals, these absorbents will not absorb water and will float indefinitely. Re-Form™ oil only absorbents made of recycled materials offer an environmentally friendly solution.

Hydraulic oil

Motor oil

Brake fluid

Cooking oil

Turpentine

Lubricants

Hazardous Chemical Fluids SPC Recommends: Chemical Absorbents

Surfactant-treated polypropylene absorbents can be used on a wide range of chemicals, including hydrofluoric acid. They are chemically inert, so they will not react with aggressive fluids. Keep in mind that absorbents take on the properties of whatever they absorb, so the bright color provides a visual indication to separate waste streams.

Acids and bases

Citric acid

Sodium hydroxide

Aggressive chemicals

General Purpose Wiping, Drips and Leaks SPC Recommends: Pads, Rolls, Socs and Pillows

Pre-cut pads and perforated rolls provide easy access to absorbents for general-purpose use around your facility. Use specialized SOCs and pillows around or underneath dripping equipment.

Heavy Foot and Forklift Traffic SPC Recommends: Mats and Rugs

Mats and rugs offer greater durability to withstand harsh conditions. Barrier-backed options prevent liquid from penetrating the absorbent and reaching the floor underneath while printed mats warn of possible slips, trips and fall hazards.

Emergency Spill Response SPC Recommends: Spill Kits, Pallets, Drain Plugs

Spill kits bundle together all of the necessary products to clean up an unexpected spill. Other spill containment options include spill pallets, drain plugs and absorbent storage centers.

Specialty Absorbents SPC Recommends: Marine or Granular Products

Marine environments require boom, sweep and drag nets to remove fluids in or near bodies of water. Granular absorbents are available when loose absorbents are preferred or when acid/base neutralization is required prior to spill cleanup.

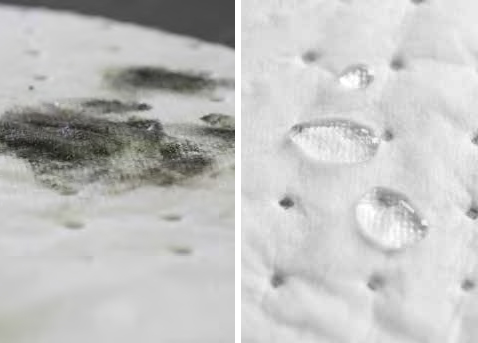

Coverstock Durability of an absorbent increases with the addition of a coverstock layer.

For simple drips or leaks, a 1-ply absorbent is all you need.

For wiping or foot traffic, a 3-ply absorbent will offer the necessary durability.

For abrasive applications, a pad with spunbond coverstock helps to reduce linting or tearing.

3-ply Construction (2-Sides Coverstock) Two layers of coverstock offer maximum durability and reduce possible linting or tearing.

2-ply Construction (1-Side Coverstock) A single layer of coverstock offers medium durability and linting.

1-ply Construction (No Coverstock) Economical single-ply has lower durability resulting in high linting and tearing.

Absorbency Weight The absorbency weight can make a significant difference in how much product is required.

For small spills, choose a light or medium weight product to avoid waste.

For large spills or continuous leaks, choose a heavy weight product to reduce total material used.

Under-Saturated Absorbents aren't being used to their full potential. You're throwing money away.

Over-Saturated Absorbents aren't cleaning the whole spill. Increase the weight to get the job done with less product.

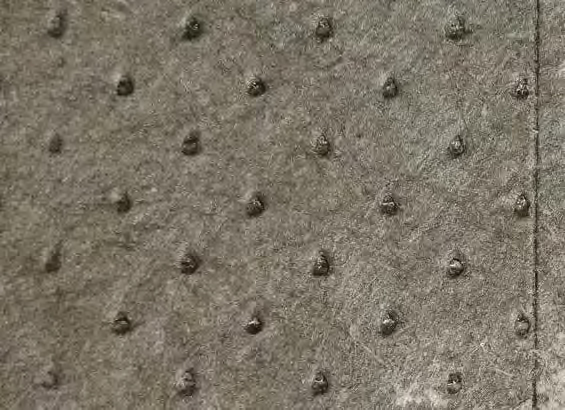

Dimpled Surface Dimpling increases product strength for areas requiring greater durability. Smooth absorbents have greater surface area and are more absorbent per square inch compared to similarly constructed, dimpled products.

Non-Dimpled Offers more absorbent surface area.

Dimpled Provides increased durability.

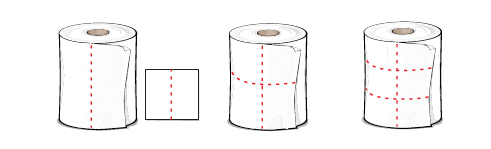

Perforations Perforations provide a variety of size options all in one product by allowing you to quickly tear off exactly what is needed to contain the spill.

Single Perf Featured on many pads and rolls.

Double Perf Featured on many rolls and mats.

Triple Perf Unique to the High Traffic Universal rolls.

Download the Chemical Application Guide.

Previously Featured on Brady SPC.

For sorbent products from Brady SPC, please visit MSCDirect.com and check out MSC's Safety Guide Book to further explore these sorbent solutions.

Use a mid- to high-level universal product, like MRO100, as the standard in your facility. Its construction can be used on a wide variety of applications and with a standardized absorbent, you will not have to manage the inventory of multiple items.

Brady SPC has been successfully developing, manufacturing and shipping absorbent products for nearly 40 years. Throughout the decades, their customers have relied on SPC products to help them prevent slips, trips and falls within their facilities. Absorbents and spill control products are its focus. Brady SPC has invested in its people, processes and facilities to ensure that it provides their customers with the best products for all their spill control needs.