The use of disposable personal protective equipment has soared since the onset of the COVID-19 pandemic, producing a huge amount of waste. Here’s how manufacturers can minimize their impact on the environment.

From disposable protective clothing to gloves, eyewear and respirators, the use of personal protective equipment (PPE) has skyrocketed in recent years as American workplaces have sought to control the spread of the COVID-19 virus.

The increased use of these items is creating a mountain of plastic medical waste that threatens to pollute the environment.

For example, according to a study in the journal Environmental Science & Technology, some 65 billion disposable gloves have been used every month during the pandemic.

That PPE waste, which is generally not biodegradable, can end up in the oceans, threatening marine life. According to the United Nations (UN), about 75 percent of the plastic waste generated by the pandemic will likely “become waste clogging our landfills and floating in our seas.”

“The negative spillover effects of plastic waste on fisheries, tourism and maritime transport, for example, add up to an estimated $40 billion each year,” the UN notes.

Finding PPE Recycling Solutions

As consumers and businesses adjust to the big changes brought about by the pandemic, there’s a potential silver lining for the environment.

According to a report by management consulting firm McKinsey, two-thirds of surveyed consumers say it has become even more important to limit impacts on climate change, with 88 percent of respondents saying that more attention should be paid to reducing pollution.

Additionally, companies have not abandoned their sustainability goals. According to BCG research, leading organizations are focusing closely on their global supply chains, looking to improve agility and efficiency. They are also working to improve the sustainability of their supply chains.

“The companies have concluded that these extra efforts are a high-payback investment, since greener supply chains can deliver benefits for both business and the environment,” according to the BCG report.

While some entrepreneurs and businesses are focused on developing reusable PPE, which can help companies manage shortages and fluctuating prices in the global supply chain, others are finding ways to turn single-use PPE into everything from bricks to toolboxes.

Kimberly-Clark’s RightCycle Program helps customers collect previously hard-to-recycle items—such as nitrile gloves, apparel items, safety eyewear and respirators—and have them turned into new consumer goods like flowerpots, patio furniture and plastic shelving. Since its launch in 2011, the program has diverted more than 1,500 metric tons of waste from landfills, according to the company.

It’s the first manufacturer-led recycling program for nonhazardous PPE, and it “enables customers to get one step closer to achieving their zero-landfill initiatives and corporate sustainability goals,” Kimberly-Clark says.

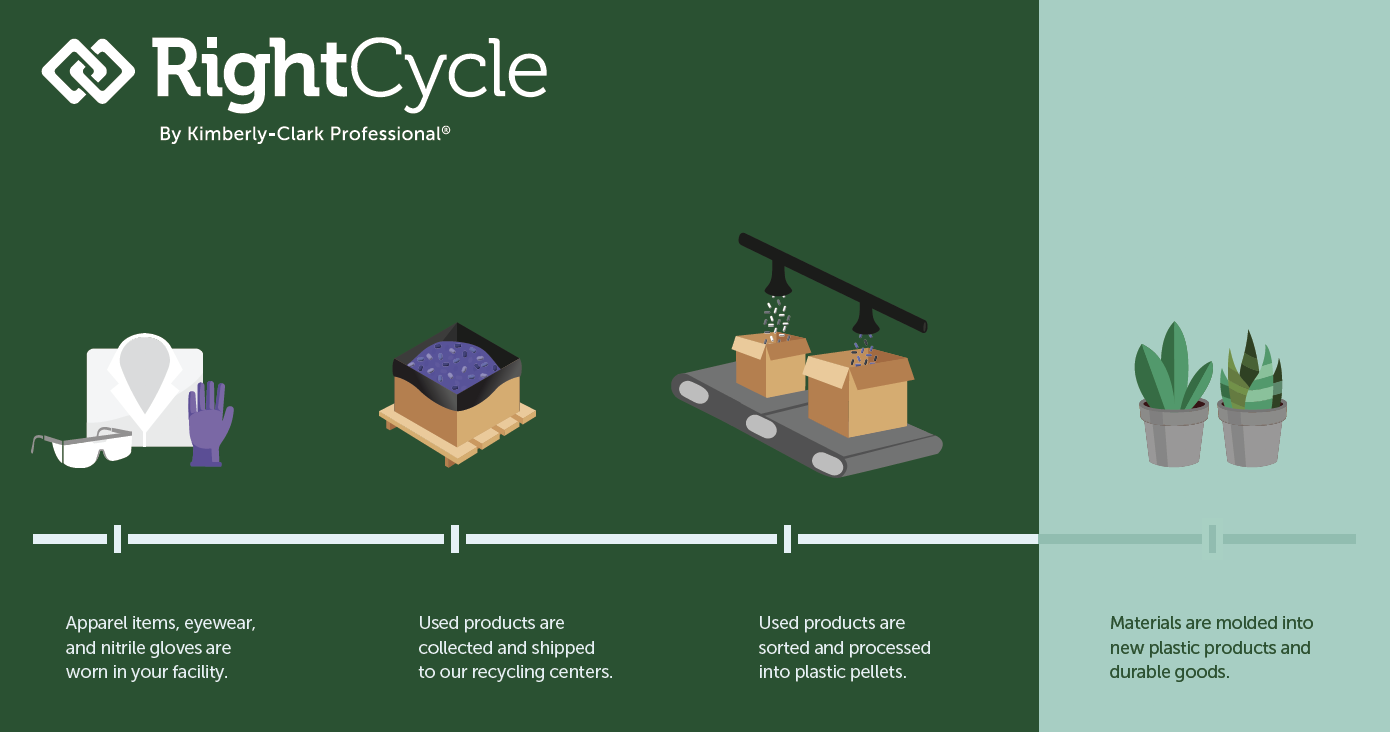

Here’s how the program works (see the graphic below for an illustration of this four-step process):

Customers use disposable PPE in their facilities—items such as eyewear or nitrile gloves that protect workers in potentially hazardous situations.

Once they are used, the products are collected and shipped to Kimberly-Clark’s recycling centers.

The used products are then sorted and processed into plastic pellets.

The plastic pellets are used to create new durable goods, such as patio furniture.

The RightCycle Program accepts the following products:

Apparel and accessories, including coveralls, lab coats, sleeves, aprons, shoe covers, bouffant caps, beard covers and face masks.

Eyewear

Nitrile gloves

Kimberly-Clark says the program is open to any company that uses its Kimberly-Clark Professional products in nonhazardous applications. More detailed information about eligible products can be found here.

RightCycle Success Stories

Kimberly-Clark points to a number of success stories associated with its RightCycle Program, including:

A partnership with Raytheon, which has enabled the major U.S. defense contractor and industrial corporation to divert 10.9 metric tons of used PPE—including gloves, apparel and safety glasses—from landfills, which is equivalent to the weight of about two light aircraft.

A program with the Dallas Zoo that has allowed the institution to divert more than 1,000 pounds of PPE waste from landfills, roughly equivalent to the weight of one of its female giraffes.

An initiative to help Coca-Cola, the world’s largest beverage company, with its World Without Waste goals, enabling the collection of hard-to-recycle items such as nitrile gloves, safety glasses and single-use apparel items at the soft drink manufacturer’s labs.

Best Practices for Organizations

In the coming months and years, as organizations learn to live with the COVID-19 pandemic and return to production levels similar to those of prior years, disposable and single-use PPE will continue to be a feature of workplaces as employers look to protect their workers.

This continued elevated level of PPE use means organizations should focus on ways to minimize their PPE waste. This may include working with initiatives such as Kimberly-Clark’s RightCycle Program.

Best practices for organizations looking to manage the growth of PPE waste include:

Setting up trash cans for collection and disposal of used PPE.

Establishing standardization, guidelines and strict implementation of waste management for PPE waste.

Investing in more sustainable PPE.

Brought to you by Kimberly-Clark Professional

Kimberly-Clark Professional* is the leader in creating exceptional workplaces, with a collection of trusted brands that help make your business safer, healthier and more productive. The Kimberly-Clark Professional brands include WypAll*, Kimtech*, Kleenex*, Scott* and KleenGuard*, making it the one source for everything from first-rate work gloves and protective apparel to high-quality wipers and odor control to superior washroom supplies.

Related Articles

Mastering the Art of Waste Walks: From Preparations to Direct Observations

Beyond the Walk: Maximize the Impact of Your Waste Walk Insights

3 Myths About Rags & Reusables

Moldex PlugStation: Bringing Hearing Protection to the People