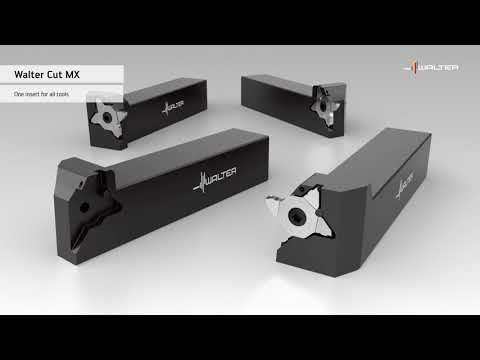

Video: Reliable Thread Turning in Tight Spaces

New indexable inserts from Walter deliver superior thread turning in tight spaces.

New indexable inserts from Walter deliver superior thread turning in tight spaces.

Walter has introduced the new A60 and AG60 inserts for small to medium pitch threads. Just like the existing MX geometries (CF5 and GD8 for grooving and parting, RF5 for grooving and copy turning), the new MX geometries A60/AG60 provide superior tool life, surface quality and process reliability. The inserts are designed with four cutting edges and are designed for thread turning operations where space is limited.

The geometries are made for creating 60° partial-profile external threads in a wide range of pitches 6-48 TPI—threads per inch (0.5–3.0 mm) and are particularly suited to thread-turning in tight spaces, like near a shoulder or counter spindle. Because of the unique insert seat pockets, inserts with different thicknesses (size 2 or size 4) as well as different function (grooving or threading) can be used in the same holder. This leads to excellent cost effectiveness and universality.

The Walter MX system is suitable for all materials and enables insert widths between 0.03-0.13 in. (0.8 and 3.25 mm) and cutting depths of up to 0.24 in. (6 mm). One special feature is the design of the insert seat. Due to its self-aligning tangential clamping, the insert is pressed against the contact points when the screw is tightened. A special dowel pin helps with accuracy of fit and simultaneously makes it impossible to mount the insert incorrectly. This results in a high degree of dimensional stability and repeat accuracy.

For a Complete Offering of Walter Tools visit MSCDirect.com.

Walter is a global leader in precision metalworking solutions, delivering high-performance tools for milling, turning, drilling, and threading. Serving aerospace, automotive, energy, and general engineering industries, we combine innovation with expertise to maximize productivity. More than a tool provider, Walter is a trusted partner, offering cutting-edge machining solutions that drive efficiency, quality, and performance in manufacturing worldwide.