Sandblasting Basics: Media, Equipment & Applications

Learn about abrasive blasting, explore blasting media types, and find out which sandblasting equipment you need for the best results for your applications.

Sandblasting, also known as abrasive blasting, is a surface preparation method that uses pressurized air to propel abrasive media to remove paint, rust, and coatings from a surface. It also cleans, smooths, or texturizes the material underneath.

Blasting media cleans, finishes, deburrs, and peens applications. Round, spherical particles create a smooth finish and lightly peen the surface, making them ideal for applications where tolerance is important. Angular, harder, or sharper media types clean more aggressively by penetrating deeper into the surface.

Grit/Grade:

Grit: Choose a smaller grit number (coarser grit) to remove material efficiently over larger contact areas. Use a larger grit number (finer grit) for applications in small areas where the final finish is essential.

Grade: Select the abrasive grade based on your surface finish needs. Use a coarser grade to quickly remove material across large contact areas. Switch to a finer grade for smaller areas where a precise finish is critical.

Materials:

- Aluminum oxide is the most commonly used abrasive. It is tough, fast-cutting, economical, and fracture-resistant. Use it on ferrous alloys, high-tensile materials, and wood. Common applications include removing paint, rust, and coatings. It is best for general-purpose deburring, blending, plating, and welding.

- Aluminum oxide–glass bead mix typically consists of 70% glass bead and 30% aluminum oxide. Use this blend when standard aluminum oxide proves too aggressive for your application.

- Crushed glass is an angular-shaped blasting media ideal for aggressive surface profiling and removing paint, epoxy, and coatings. Crushed glass blasting media is free of heavy metals like lead, asbestos, and titanium, making it a safer blasting option.

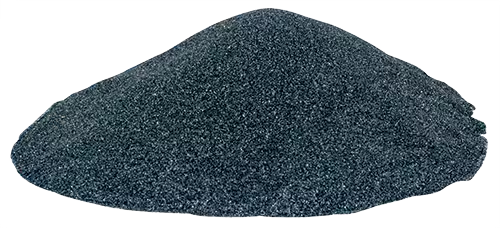

- Silicon carbide is the hardest and fastest-cutting blasting media available. Its high cutting speed and abrasive hardness reduce blasting time. It contains no free silica, doesn’t create static, and can be recycled multiple times. Use it on nonferrous metals and in low-pressure blasting applications.

- Garnet is a fine-cutting abrasive that quickly removes rust, corrosion, and coatings from the substrate. It also works well for removing burrs and preparing metal for coating.

- Glass bead is commonly used in blast cabinets for honing, polishing, peening, finishing, and removing light burrs. It produces a clean, bright satin finish without dimensional change of the part and peens surfaces without overstressing the metal.

- Walnut shell is an angular media ideal for cleaning soft metals like aluminum without damaging the substrate.

Abrasive Media Comparison Chart

Glass Bead | Garnet | Crushed Glass | Walnut Shell | Silicon Carbide | Aluminum Oxide | Aluminum Oxide Glass Bead Mix | |

|---|---|---|---|---|---|---|---|

Cleaning Speed | Med | High | High | Med | High | Med/High | High |

Cleaning Metal | Med | Good | Good | Low | Very Good | Good | Med |

Blast Pressure | 20-60 | 60-100 | 20-50 | 20-60 | 20-90 | 40-90 | 20-60 |

Metal Removal | Very Low | High | Low/Med | Low | High | Med/High | Med |

Hardness (MOH Scale) | 5.5 | 7.5 | 5.5 | 1-4.5 | 9 | 9 | 5.5-9 |

Shape of Granule | Spherical | Granular | Spherical | Granular | Angular | Angular | Spherical/ Angular |

Dust Level | Low | Med/High | Low | Low | Med | Med | Med |

Continued Use Ability | Med/High | Med | Low | Low | Low/Med | Med/High | Med/High |

Blasting Equipment from MSC Industrial Supply

Sandblasters

Sandblasters clean, strip, and finish large metal surfaces. They also remove paint, rust, or any other surface material. Choose from free-standing cabinets, bench-top cabinets, handheld, and portable kits.

Guns and Nozzles

Guns and nozzles can make all the difference when blasting media. Create a uniform pattern when using fine-to-medium grains by controlling the way the abrasive media flows while working. Find nozzle and jet materials, including aluminum, tungsten carbide, and hardened steel.

Sandblasting Cabinet Accessories

Sandblasting cabinet accessories can help your cabinets perform continuously at peak performance. Select from cabinet replacement parts, dust collectors, turntables, underlayment, and filter bags.