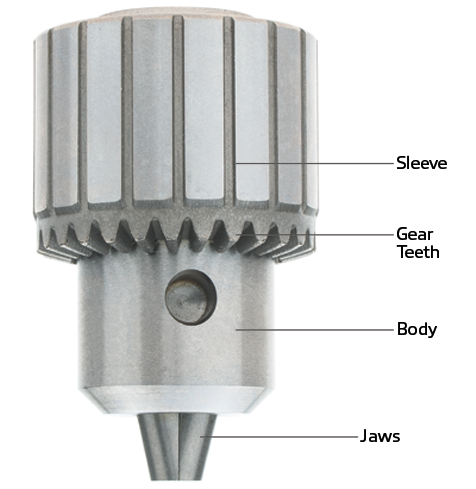

A drill chuck is a device that securely holds a drill bit or other cutting tool on a spindle. The different types of drill chucks —keyed, keyless, and hybrid— allow for quick changes of a drill bit and offer various benefits depending on your application.

Drill Chucks Built for Accuracy

Learn how to choose the right keyed, keyless, or hybrid drill chuck for your tool, application, and precision needs.

Drill Chucks

Types of Drill Chucks

Drill Chuck Mount Types

Mount type refers to how the drill chuck connects to an arbor, shank, or spindle.

- Integral shank drill chucks: Arbor (shank) is built into the drill chuck, providing greater rigidity and concentricity than a press-fit tapered mount.

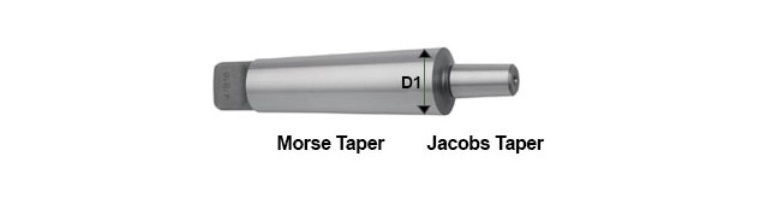

- Tapered mount drill chucks: Use an internal Jacobs Taper (JT) press-fit onto a matching JT arbor (shank) or spindle.

- Threaded mount drill chucks: Internal threads secure the chuck to a spindle or threaded arbor.

Taper Dimensions: Drill Chuck Taper Mount Size

Morse Taper Dimensions

Morse Taper | 1 | 2 | 3 | 1 | 2 | 3 |

|---|---|---|---|---|---|---|

D1 | 0.481" | 0.709" | 0.947" | 1.244"" | 1.7613" | 2.510" |

Jacobs Taper Dimensions

Jacobs Taper | 0 | 1 | 2 | 3 | 4 | 5 | 6 | 33 |

|---|---|---|---|---|---|---|---|---|

D | 0.250" | 0.384" | 0.559" | 0.811" | 1.124" | 1.413" | 0.676" | 0.624" |

Drill Chuck Bearings

Ball Bearing

Ball bearings are designed to reduce friction in the tightening mechanism and provide a better grip on the drill. They are ideal for heavy-duty machining and require a key for tightening or loosening.

Plain Bearing

Plain bearings feature a one-piece gearing and sleeve for reducing tooth breakage. They are ideal for medium-duty operations with stationary drilling, turning, milling, and woodworking machines.

Plain Bearing Keyed Chucks

Designed with one-piece gearing and a durable sleeve to minimize tooth breakage. Ideal for medium-duty industrial use in stationary drilling, turning, milling, and woodworking machines. Available with threaded mounts for hand-held drills and tapered mounts for stationary machines where run-out is not a critical factor (up to approx. 0.004″).

Light-Duty Keyed Chucks

Cost-effective for basic DIY work. Nowadays, they are often being replaced by keyless chucks. Ideal for electric hand-held drilling machines, reversible or non-reversible.

Stainless Steel Keyed Chucks

For use in the food, medical, and dental industries, where tools must be sterilized.

CNC Precision Keyed Chucks with Integrated Shank

Engineered for CNC machines, these chucks feature a short design for maximum concentricity and exceptional precision (max. run-out of 0.0012″ or better). Delivering high clamping forces of over 75 ft./lbs., they offer optional through-coolant capability and support both clockwise and counterclockwise rotation. Ideal for high-speed CNC milling, drilling, reaming, and tapping applications.

Keyless Drill Chuck Styles

High-Precision/High-Torque Keyless Drill Chucks

Designed for applications requiring extreme accuracy, these chucks feature a self-tightening mechanism that grips tighter as torque increases. Suitable for high-accuracy drill presses, jig borers, milling machines, CNC equipment, and production drilling. Minimum run-out: TIR .0016″ or better. Clockwise operation only.

Medium-Duty Keyless Drill Chucks

Offer the same self-tightening feature as high-precision models but with a slightly wider run-out (approx. .006″). Ideal for medium-duty industrial applications and available in threaded mounts for hand-held drills or tapered mounts for stationary machines. Clockwise operation only.

Stainless Steel Keyless Drill Chucks

Corrosion-resistant, self-tightening chucks built for industries requiring sterilization, such as food processing, medical, and dental. Clockwise operation only.

Portable Drill Keyless Chucks

The latest generation for power tools, featuring ergonomic designs with plastic or metal sleeves. Many models include a locking mechanism for hammer drilling or screwdriver operations. Compatible with reversible and non-reversible hand-held drills.

CNC Precision Keyless Drill Chucks with Integrated Shank

Compact, rigid construction with high precision (TIR .0016″ or better). Self-tightening for maximum grip, designed for CNC milling, turning, and stationary machines requiring clockwise operation.

Drill Chuck Materials

Mounting & Removing Drill Chucks

On Threaded Spindle Portable Tools

Unplug the drill or disconnect the battery pack.

Open the jaws of the existing chuck completely.

Remove left-hand thread screw, if any, from inside chuck and save for re-use.

Insert the hex-type wrench into the chuck body and tighten the jaws on the wrench.

Strike the wrench counterclockwise with a mallet to free and unscrew the chuck.

Screw the new chuck onto the spindle (clockwise).

Insert the hex-type wrench in the jaws and tighten the jaws on the wrench.

Strike the wrench clockwise with the mallet several times.

On Tapered Shank Arbors

To mount chucks

Clean both tapers of all grease and grit. With the jaws retracted into the chuck and with the chuck nose resting on a wooden bench, strike the tang of the arbor lightly to seal it into the chuck.

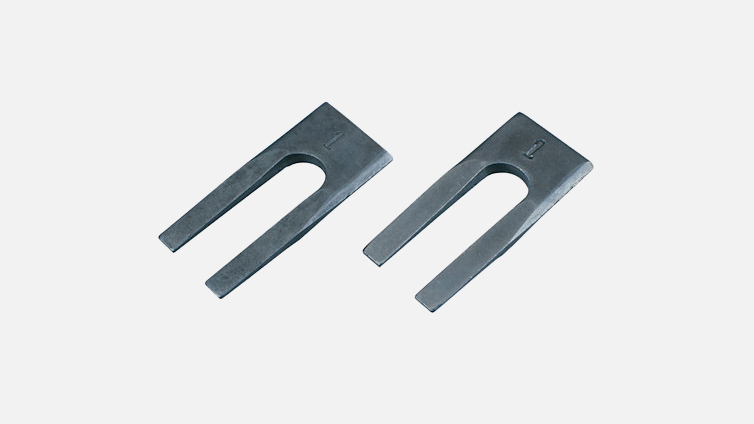

To remove chucks

Insert a wedge between the back of the chuck and the shoulder of the arbor. In case the mounting taper of the arbor does not provide a shoulder, a cross hole should be drilled through the neck of the arbor and a cross pin inserted. Then the wedge can be used between the chuck back and the cross pin to free the chuck from the arbor.