Thread mills are for cutting internal and external threads. They are ideal for threading exotic materials and soft, nonferrous alloys (where tap breakage is often a problem). Thread milling also provides smaller cutting forces, allowing for the threading of thin-walled parts. These tools can be used on materials up to 60 HRC and can cut any large internal thread if the pitch stays the same. For example, an 11/16-16 internal thread can be cut by a thread mill that is rated for the 9/16-16 thread.

Thread Milling Tech Guide and Diagrams

Learn more about thread mills with our detailed diagrams and guides. Discover the types, finishes, and materials you need for your industrial projects.

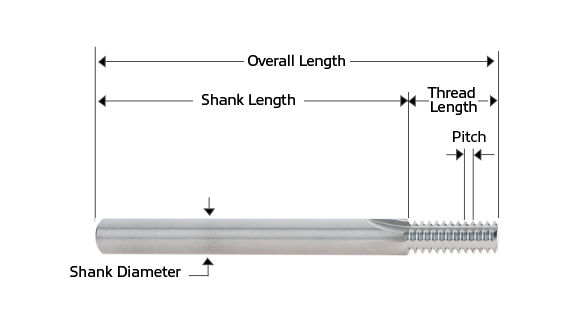

Diagram of a Thread Mill

Advantages of a Thread Milling Machine

- Complete operation in one setup

- No upper limits to bore size

- One tool will cut many different diameters

- Short, manageable chips produced

- Threads can be machined within 1/2 pitch of the bottom of blind holes

- One tool cuts right- and left-hand threads

- Easily machine threaded parts with interrupted cuts

- Shorter cycle times due to higher cutting speeds and rapid feed rates

- Better finish produced over tapping

- Lower horsepower is required than for tapping

- It’s easier to thread mill hard materials compared to tapping

- Better thread quality in soft, gummy materials (where taps normally tear the material)

Types of Thread Mills

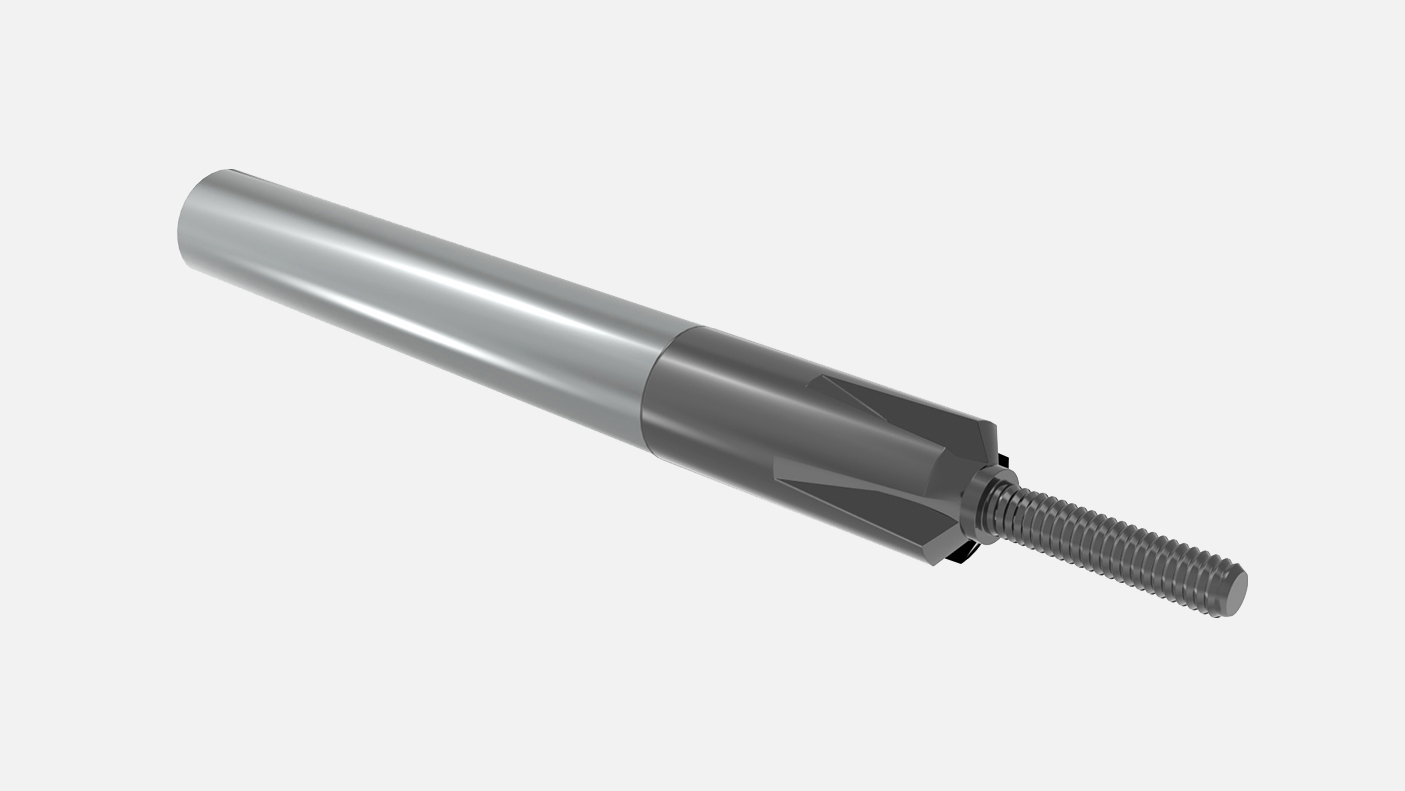

Helical Flute Thread Mill

Helical flute thread mills are for cutting internal and external threads in high-speed applications. The helical design reduces cutting pressure, providing a smoother finish on the workpiece. It’s ideal for tough and thin-walled materials.

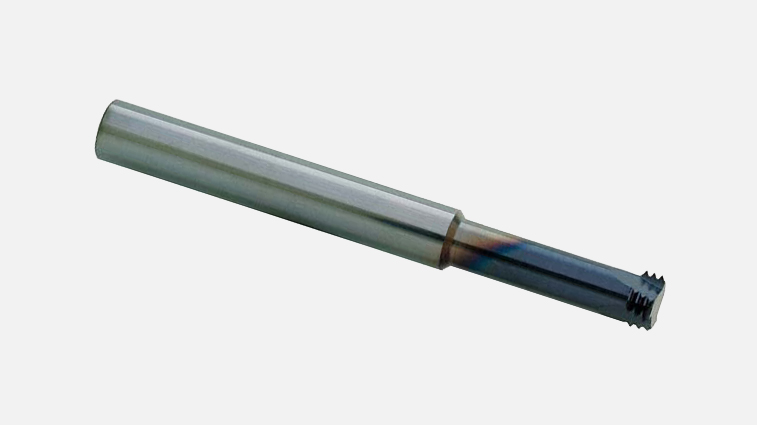

Straight Flute Thread Mill

Straight flute thread mills are for cutting internal and external threads in general-purpose applications. There is one tooth per thread on each face. Select this for effective, rapid cutting or stable setups.

Single-Profile Thread Mill

Single-profile thread mills are for cutting internal and external threads. The multiple flute design cuts threads in a variety of pitch ranges, lengths, and diameters. It’s exceptional for workpieces with unfavorable length-to-diameter ratios and applications that need very low side cutting pressure.

Standard Finishes:

Bright provides a smooth, polished finish on the tool. It increases chip flow in softer materials such as aluminum, wood, and plastic.

Titanium Nitride (TiN) is a multi-purpose coating that increases chip flow in softer materials. The heat and hardness resistance allow the tool to run at higher speeds than uncoated options.

Titanium Carbonitride (TiCN) is harder and more wear-resistant than TiN. Use this on stainless steel, cast iron, and aluminum alloy.

Oxide, also known as black oxide or steam oxide, is a surface treatment that prevents chip building, galling, and welding on the workpiece. It is common for projects with low carbon, stainless steel, and ferrous metals.

Chrome Plate is a bright, electroplated coating that offers excellent anti-friction properties. It is commonly used on steel, aluminum, brass, copper, or other nonchromium materials.

Nitride is a thin, hard-shell coating that supports the surface hardness of the tool. It is for use in abrasive or wearing conditions.

Aluminum Chromium Nitride (AlCrN) has higher-heat resistance than AlTiN. It is common for machining aircraft and aerospace materials, as well as nickel alloy, stainless steel, titanium, cast iron, and carbon steel.

Aluminum Chromium Titanium Nitride (AlCrTiN) is a highly heat- and wear-resistant, multilayered PVD coating. It enhances tool life and provides a superior thread finish.

TiCN PLUS Titanium Carbon-Nitride (TiCN) plus Titanium Nitride (TiN) is an all-purpose finish that increases tool life by two to four times more than TiN-coated tools. The heat and hardness resistance allow the tool to run at higher speeds than uncoated versions.

Uncoated tools do not feature supportive treatments on the cutting edge. They are for working at reduced speeds in general applications on nonferrous metals.

Standard Materials:

Cobalt is harder than high-speed steel and provides better wear resistance. It is commonly used on high-tensile alloys.

High-Speed Steel (HSS) provides good wear resistance and can be used in general-purpose applications for both ferrous and nonferrous materials.

Solid Carbide provides better rigidity than high-speed steel. It is extremely heat-resistant. Use this for high-speed applications on cast iron, nonferrous materials, plastics, and other tough-to-machine materials.

Vanadium High Speed Steel (HSSE) features a combination of materials: high-speed steel, carbon, vanadium carbide, and other alloys. This construction increases abrasive wear resistance and toughness. HSSE is for general applications on stainless steel and high-silicon aluminum.

Powdered Metal (PM) is tougher and more cost-effective than solid carbide. This material works well on highly abrasive materials (including high-silicon aluminum).

Terminology:

Pitch: The distance between a point on a screw thread and a corresponding point on the next thread. The pitch is equivalent to one divided by the number of threads per inch.

Threads per Inch (TPI): Refers to the total number of threads within a one-inch space on the mill. Higher numbers of threads per inch provide smoother cuts, while fewer numbers of threads provide coarser cuts.

Cutting diameter: Refers to the cutting portion of the thread mill. The cutting diameter is for programming speeds. Internal threads must be smaller than the nominal diameter of the drilled hole.

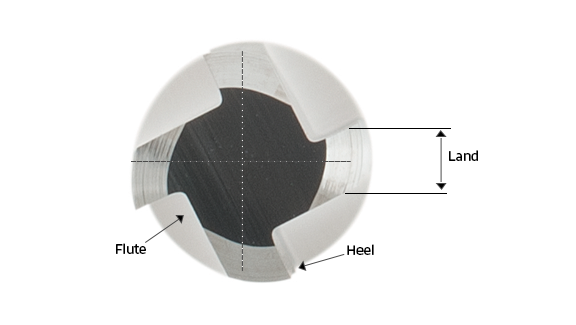

Number of flutes: Refers to the number of grooves or valleys that are cut into the body of the thread mill. Higher numbers of flutes increase the strength of the thread mill and reduce space or chip flow. This can also decrease cycle time and increase tool life.