High-Tech for Cutting Tools

Special coating technology improves finishes on difficult-to-machine materials and offers longer tool life.

Special coating technology improves finishes on difficult-to-machine materials and offers longer tool life.

Walter is tackling difficult applications in hard-to-machine materials with its innovative HIPIMS PVD coating technology, and reaping benefits in terms of accuracy, surface finish and tool life.

Design and manufacturing don’t stand still. Change is ceaseless, and with change comes new challenges. Case in point, the search for smaller, lighter and stronger components. This trend is shaping many areas of industry— from aerospace to the automotive industry, right through to medical device manufacturing. Miniaturization and/or lightweighting typically demands higher dimensional accuracy and surface finish and increased use of difficult-to-machine materials such as high-temperature alloys, titanium alloys, cobalt-based alloys, and nickel-based alloys such as Inconel 718.

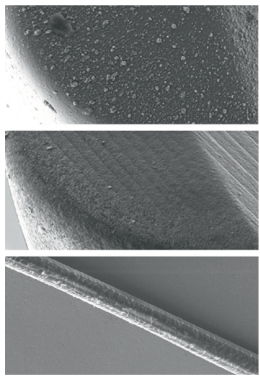

Waukesha, Wisconsin-based Walter has a solution for this range of applications – high power impulse magnetron sputtering (HIPIMS) physical vapor deposition (PVD) coating for cutting tools. In contrast to conventional PVD processes, HIPIMS subjects the target to short pulses of a few kilowatts of power, producing extremely smooth surfaces, lower friction and edge build-up, excellent bonding of layers to the substrate and layer thickness distribution.

Hard, very tough materials that are becoming popular (such as Inconel 718DA with 42HRC in the aerospace industry or Ti-6Al-4V in the medical industry) have complex requirements for indexable inserts. Tough materials have a high tendency for adhesion, especially when they have a high nickel content, causing chips to stick to the cutting edge and form build-up. Dimensional stability and surface quality suffer. Accelerated wear on cutting edges had to be accepted until now, especially in the case of high-strength materials.

During turning operations on conventional materials with high-to-medium depths of cut, chemical vapor deposition (CVD)-coated indexable inserts, which have previously dominated the market, offer good-to-outstanding possibilities. However, these inserts reach their limits in machining applications on difficult-to-machine alloys and in finishing and fine finishing applications, particularly where precision and tool life are concerned.

Gerd Kussmaul, senior turning product manager at Walter, describes the concept behind the new HIPIMS PVD-coated indexable inserts.

“Even if the fine finishing and finishing of ISO M, S, P and N materials with the highest requirements for surface quality are still special or niche applications, we see great potential due to dynamic growth in the market right now,” Kussmaul says. He explains that fine finishing involves turning operations which are designed to achieve a consistently good surface quality.

“Walter has been looking for geometries and cutting tool materials that achieve this with process reliability,” Kussmaul explains. “The new PVD HIPIMS coatings demonstrate ideal properties for achieving extremely smooth surface and great layer adhesion on sharp cutting edges.”

For the hard and tough alloys like Inconel and titanium alloys, sharp cutting edges are needed even for higher feed rate and depth-of-cut operations ranging into medium machining to light roughing. Due to the tendency of nickel and cobalt alloys to work harden during machining, sharper edges reduce this effect and the depth-of-cut notching wear that it creates. The sharper edges also reduce build-up on the cutting edge, which becomes more likely as feed rates increase.

Finishing inserts with extremely sharp edge geometries, such as the FN2 or the MN2, as well as medium geometries like the MS3, benefit from this coating process because extremely stable cutting edges are produced. Even under high loads, the layers do not chip off and the cutting edges do not break away. In addition, the high level of edge stability ensures lower levels of more even wear. Even wearing ensures dimensional stability and surface quality throughout the tool’s life.

Extremely smooth HIPIMS coatings are ideal for machining sticky aluminum alloys for example. These and other materials, which would otherwise stick to the cutting edge during machining, now reliably glide over it. Typical forms of wear, such as built-up edges or significant flank face wear, caused by chemical and physical reactions with adhering the workpiece rarely occur.

As Kussmaul notes, people don’t necessarily change from a tried-and-true cutting tool material without good reasons.

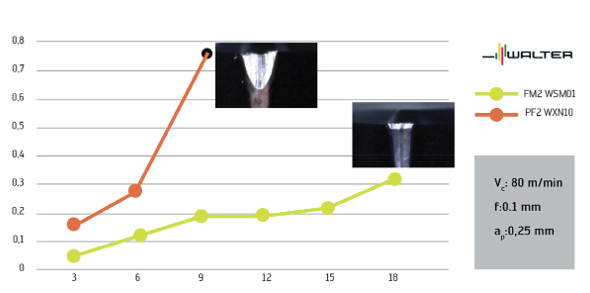

“Among other factors, the outstanding results achieved by the new HIPIMS grades regarding tool life and surface quality speak in their favor. This is clear from comparative tests,” Kussmaul says.

When performing finishing operations on tool steel H13 with 54 HRC, it was possible to increase the tool life by 275%. And the surface value of Ra 0.8µm was achieved throughout the entire tool life with process reliability.

Kussmaul describes another application: finishing Inconel 718DA at a cutting speed of 262 FPM, with the new grade WSM01 and achieving a cutting time and tool life of 18 minutes – double the previous WXN10 grade.

Walter's HIPIMS PVD indexable inserts can be used anywhere that maximum process reliability, precision, and surface quality are required, particularly when dealing with difficult-to-machine materials. Inserts lower costs because the HIPIMS PVD coating, in conjunction with a carbide substrate, results in a cutting tool material with consistently high machining quality and long tool life. This is especially true for difficult machining such as fine finishing and for sticky materials such as aluminum alloys with high silicon content. Tool life and surface quality gains compared to previous indexable inserts are dramatic, often leading to significant cost reductions.

Previously Featured in Aerospace Manufacturing and Design.

Walter is a global leader in precision metalworking solutions, delivering high-performance tools for milling, turning, drilling, and threading. Serving aerospace, automotive, energy, and general engineering industries, we combine innovation with expertise to maximize productivity. More than a tool provider, Walter is a trusted partner, offering cutting-edge machining solutions that drive efficiency, quality, and performance in manufacturing worldwide.