Grinding wheels can be extremely dangerous. If you over-rev the wheel, and it has microscopic defects or cracks, it may shatter, sending shrapnel everywhere and possibly injuring you or a co-worker. Here’s what you need to know about the proper care and maintenance of your grinding wheels.

Despite its long history, its extreme precision and its ability to machine even the hardest of metals to a glasslike finish, grinding remains a bit of a black art.

With a host of variables that include grit size, bond and the abrasive itself, it can be challenging to find the optimum wheel for a given grinding application, let alone use and care for it properly. Fortunately, there are loads of people offering free advice on the subject—the experts cited in this article among them—all of whom have plenty to say about this last part: the care and handling of grinding wheels.

Like Fine China

Of course, we’re talking about cylindrical, centerless and surface grinding, not the portable grinding used to smooth a welded joint or that used to machine carbide cutting tools and inserts. And in the majority of precision grinding operations, that means vitrified wheels. That’s according to Trish Dawson, product manager for bonded abrasives at Norton Saint-Gobain Abrasives, who says nonwoven and organic wheels have their place, but for precision grinding operations, the glasslike bond of vitrified abrasives is the first and often the only choice.

Note that last term: glasslike. It may seem improbable that such a hard object is anything but durable, yet the fact remains that grinding wheels require special handling.

“Vitrified bond wheels are fired at high temperature and attain a structure similar to glass or ceramic,” she says. “Handle it as you would a dinner plate, because if you treat it badly, it’s apt to get a catastrophic crack and quite possibly break apart during use.”

Read more: 5 Ways Manufacturers Can Use Data Analytics to Improve Efficiency

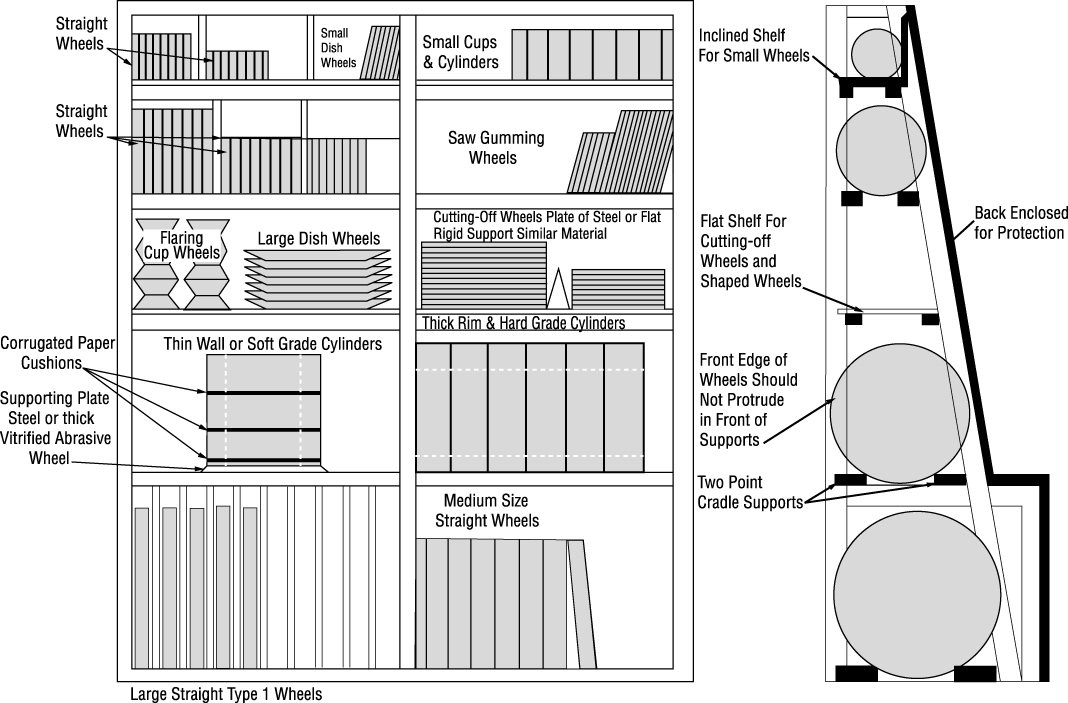

It’s for this reason that she and Rodney Finch, precision grinding application manager at CGW Abrasives, agree that shops should store wheels much as they would their china at home—in a cabinet, where they’re protected from being banged into or knocked over.

“A pegboard is fine as well, but it’s important that the wheels don’t touch one another and that nothing bumps into them,” he says. “Laying them down is OK, provided there’s some sort of cardboard or wooden divider between each one. Otherwise, it’s usually best to stand wheels on edge, especially larger ones, since it makes them easier to pick up and offers the least potential for damage.”

Shops should store wheels much as they would their china at home—in a cabinet, where they’re protected from being banged into or knocked over. (CGW Abrasives)

How to Perform the Ring Test

Just like fine china, an undamaged wheel will ring when tapped in a certain way. Grinding experts call this the “ring test,” and it’s something that should be done before mounting any wheel to an arbor:

The wheel should be dry and free of any foreign material. Visually inspect it for cracks, chips and other damage.

Suspend the wheel on a pin or hangar. Large wheels can be stood on edge on a clean, hard surface.

Using a light, nonmetallic implement (a screwdriver handle does a fine job), gently tap the wheel 1 to 2 inches from the periphery and 45 degrees to either side of the wheel’s vertical centerline.

Rotate the wheel 45 degrees and test again. Each tap should produce a clear ringing sound like that of a bell. Cracked wheels will emanate a dull thud and should be disposed of immediately.

These steps are outlined in OSHA standard 1910.215 and most grinding wheel manufacturers’ websites. While you’re there, also download ANSI standard B7.1, Safety Requirements for the Use, Care & Protection of Abrasive Wheels, a document that Norton Saint-Gobain refers to as the bible of grinding wheel safety.

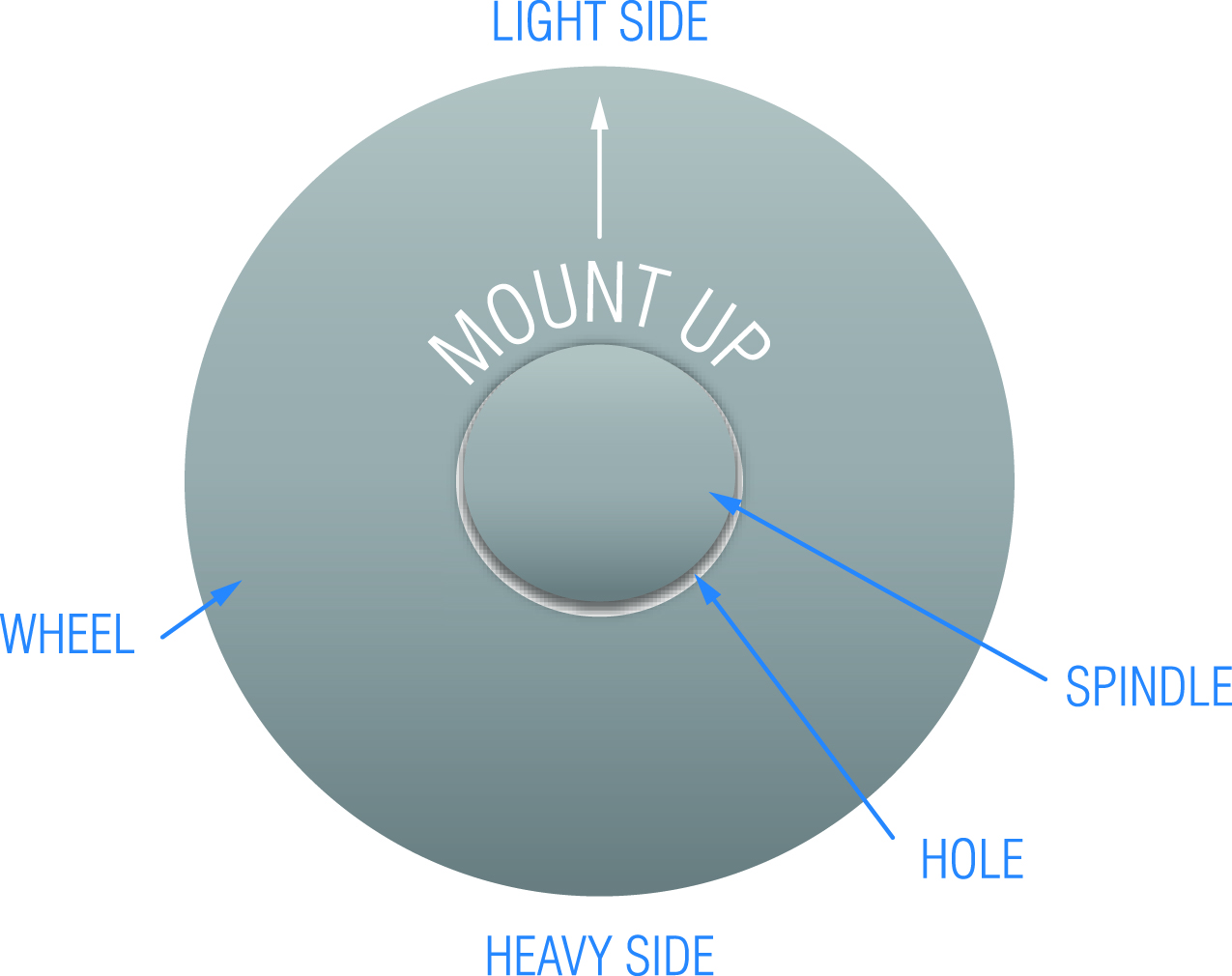

A “mount up” arrow on the wheel face should point upward when attaching the flange. (Norton)

Read more: Good Vibrations: How to Optimize Your Machine Setups to Minimize Chatter

Balancing the Wheel

Someone who knows this standard well is Debra Williams, senior product safety engineer for Norton Saint-Gobain Abrasives.

She’ll tell you to ring-test every wheel before mounting, including wheels that have been removed from their arbors. Even wheels that pass the test should be allowed to spin at the recommended rpm for at least one minute with no one standing near the machine, lest unexpected failure occurs. “This can happen if the wheel is out of balance or has been mounted improperly,” she adds.

These last two points—mounting and balancing—are every bit as important to wheel safety as the ring test. Williams offers these recommendations to make sure your grinding wheel doesn’t become like a bad tire, ready to put even the best of drivers in the ditch:

Always use the correct size blotters, the doughnut-shaped compressible washers that sit between the wheel and flange. Use only blotters that are supplied or recommended by the abrasive wheel manufacturer.

Always use matching flanges, which should be properly relieved and sized to the wheel. Also inspect the flanges to make sure that they are flat and are in good condition (clean and free of burrs).

If a “mount up” arrow is present on the wheel face, it should point upward when attaching the flange.

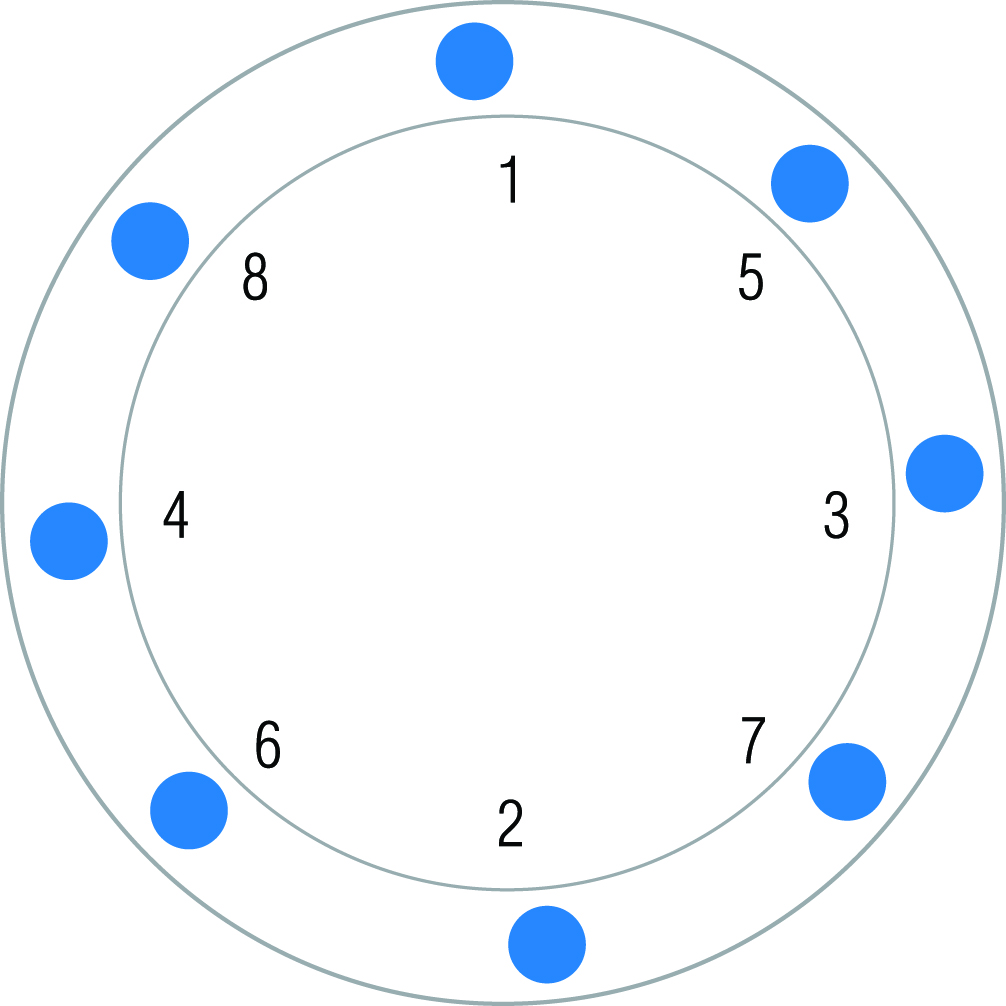

Just like mounting a wheel on your car, follow the manufacturer’s bolt tightening sequence and torque recommendations.

Assuming your grinder is not equipped with an automatic balancing system, always balance wheels before mounting in the machine.

Always use the correct spindle rpm relative to the wheel size and type. Never run a machine without the proper guarding, a practice that Williams says happens all too frequently.

Run the wheel with the coolant turned off for a minute or two before stopping the wheel to avoid an out of balance condition.

And always use the correct truing and dressing procedures.

Follow the manufacturer’s bolt tightening sequence and torque recommendations. (Norton)

Read more: Managing Downtime: A Guide to Improving Shop Productivity During Manufacturing Slowdowns

Dressing Up

This last part is a critical part of grinding success. CGW’s Rodney Finch notes that the step is often overlooked, and that dressing should not only occur at the right intervals, but also for the right reasons—doing so can improve productivity upward of 30 to 40 percent.

“Let’s say you’re grinding a gummy material that’s causing the wheel to load up,” Finch says. “You might respond by dressing more frequently, but chances are good that you have the wrong wheel, and you’re just masking the problem. This kind of thing happens all the time.”

Trish Dawson agrees: “This is why most wheel manufacturers, Norton included, have a troubleshooting guide in their catalog or available on their website,” she notes. “Is the wheel too soft, too hard, the wrong grain size, the wrong bond? There are a lot of variables, but one thing is certain: There’s no reason to settle for poor grinding performance.”

Finding the Best Wheel for Your Setup

CGW Abrasives, Norton Saint-Gobain Abrasives and other grinding wheel manufacturers offer hundreds of high-quality products, and they develop new ones each year. Each company will tell you that wheel selection starts with finding the correct wheel size and shape for the application, the grit size and type of abrasive, the wheel hardness and bond and then following the manufacturer’s usage recommendations.

And while they and others encourage shops to optimize their grinding operations with revolutionary wheel technology designed for new materials and able to deliver enhanced grinding performance, some might be better off spending their money elsewhere.

“People read a magazine article or talk to their abrasive salesperson and decide to give it a try,” says Rodney Finch, precision grinding application manager at CGW Abrasives. “The problem is, their machines aren’t always up to the task.”

Using superabrasives or the latest and greatest ceramic wheels on a Korean War-era Brown and Sharpe surface grinder is asking for trouble, Finch adds. Just like using a high-tech grade of coated carbide on an Acme-Gridley screw machine, it's likely that the spindle will be underpowered, the ways too worn, and the machine itself less rigid than is needed for optimal cutting.

“I often found in these situations that they should save their money and go with a plain old white aluminum oxide wheel from yesteryear,” he adds.

Related Articles

Collets Explained: A Guide to Types, Applications and Proper Selection

Zero Scrap and Performance Upgrade

The Latest Tools and Techniques in Metal 3D Printing

HOW TO Put Innovation to Work for You