OSG A Brand AT-2 Thread Mill: 2 Processes with 1 Tool

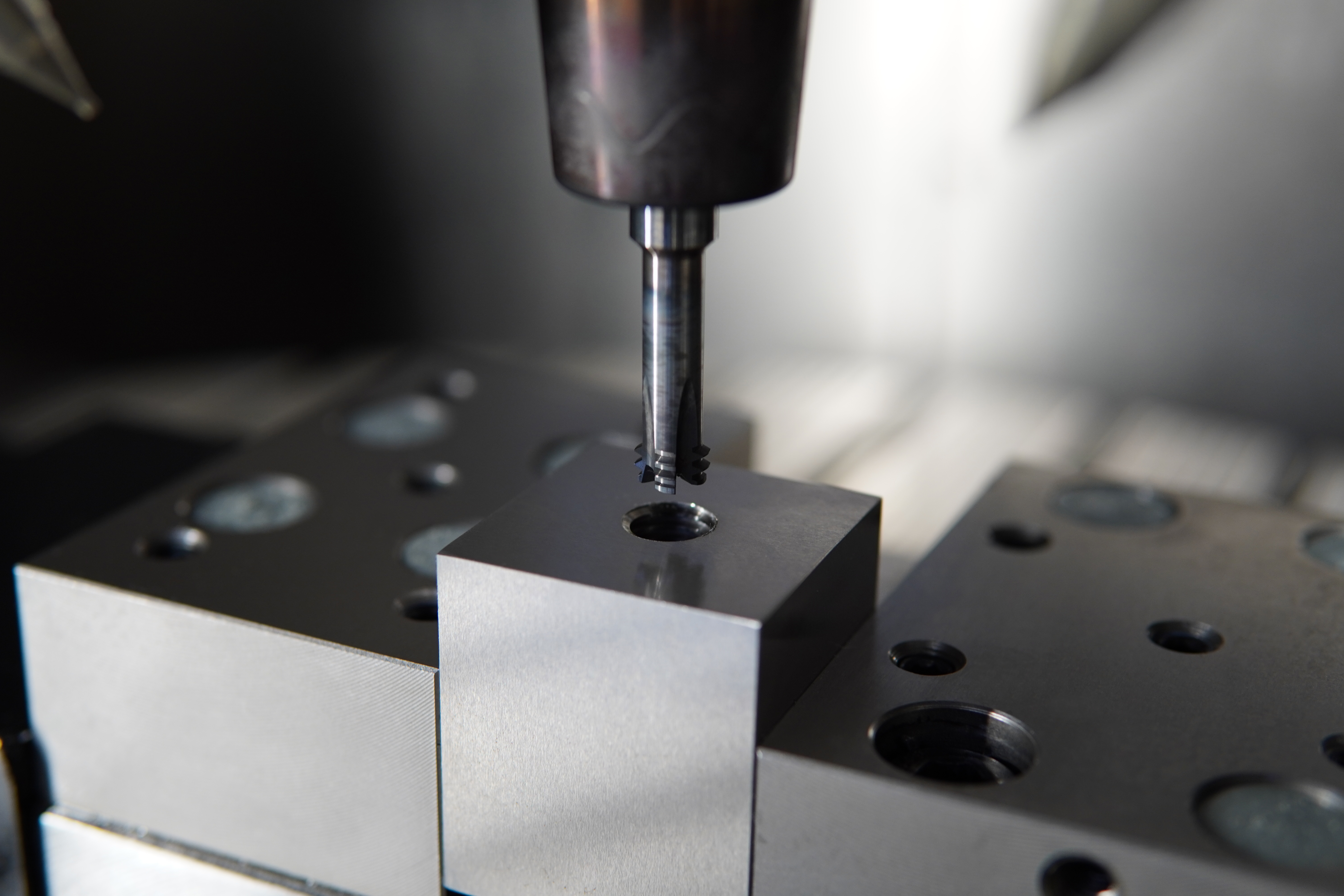

The OSG A Brand AT-2 Thread mills with end-cutting edge for high hardness steels is ideal for highly difficult high hardness steel applications.

The OSG A Brand AT-2 Thread mills with end-cutting edge for high hardness steels is ideal for highly difficult high hardness steel applications.

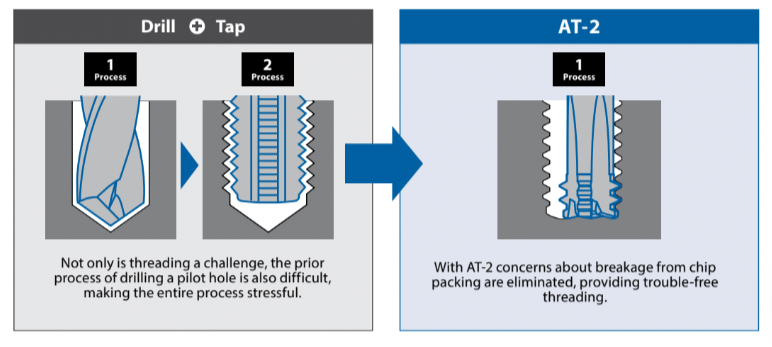

The OSG A Brand AT-2 Thread mills with end-cutting edge for high hardness steels is ideal for highly difficult high hardness steel applications. The risk of sudden tool breakage can be minimized by breaking chips into small and manageable pieces and evacuating them smoothly. Since no pilot hole is required, process integration and the risk of breakage can be avoided.

Customers threading high hardened materials

Customers looking for thread processing efficiency

Combining drilling and threading simultaneously, great cycle savings can be achieved

By eliminating drilling and tapping operations, tool breakage in the hole can be eliminated, thus eliminating tool removal processes

End Cutting Geometry with Roughing Teeth

Helical drilling while rough cutting the thread form suppresses bending of the tool with load

Left Hand Cutting

Tool specification enables climb cutting which prolongs tool life

DUROREY Coating

New SUPER coating technology provides superior heat resistance and high toughness, optimized for high-hardened materials

OSG’s DUROREY coating enables superior heat resistance and high toughness optimized for high-hardness steel milling.

Special cutting edge shape controls tool deflection.

Left-hand cut configuration enables climb milling to prolong tool life.

Added roughing teeth to distribute the load.

No pilot hole is required Helical drilling + threading can be done simultaneously.

Watch now: See the AT-2 Thread Mill in Action

Helical drilling and threading are performed simultaneously, which reduces the risk of potential machining problems in the processing of high hardness steels.

The risk of sudden tool breakage is minimized as the chips are broken into small, manageable pieces and evacuated smoothly. Since no pilot hole is required, AT-2 integrates two processes while avoiding part scrap.

Previously Featured on OSG's website.

OSG® is known worldwide for manufacturing premium round cutting tools for the metalworking industry. OSG remains focused on producing the highest quality and most consistent performing threading, drilling and milling tools. OSG provides a total solution of metalworking tools including spiral point taps, jobber length drill bits, square end mills, ball end mills and roughing end mills.