A Chemical Glove Program is an important part of managing safety in your operation. Workers face a wide range of risks when they are exposed to chemicals as part of their daily tasks. They need to feel equipped against exposure to harmful chemicals, as well as incidental cuts and abrasions, by using the right hand and body protection equipment. This guide serves as an overview of factors in the selection of the right glove in various chemical environments.

Factors in Chemical Glove Selection

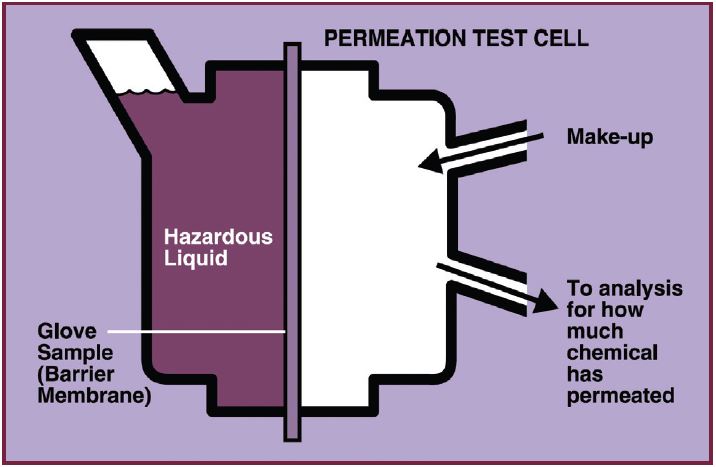

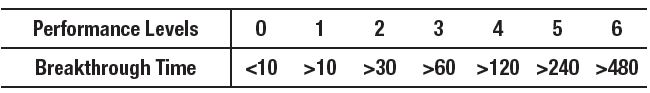

Permeation can be impacted by the working temperature of the surroundings and/or chemical. The higher the working temperature, the lower the breakthrough time and vice-versa. Times noted per the standard are based on working at room temperature.

Breakthrough time > 30 min. for at least three chemicals from this list (XYZ represent the code letters for three of these chemicals for which the glove obtained > 30 min. breakthrough time):

A. Methanol G.Diethylamine

B. Acetone H.Tetrahydro

C. Acetonitrile I. Ethyl Acetate

D. Dichlonomethane J. n-Heptane

E. Carbon Disulphide K. Sodium Hydroxide 40%

F. Toluene L. Sulphuric acid 96%

Low Chemical Resistance

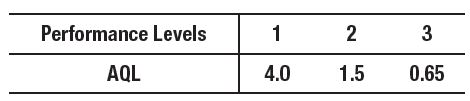

This icon can be used for gloves that do not meet the above requirement and have an AQL of 1.5 or lower.

Micro-Organisms

A glove shall not leak when tested to an air and/or water leak test, and shall be tested and inspected in compliance with the Acceptable Quality Level.

Only applies if the AQL is equal to or below 1.5

For more technical information regarding chemical hand protection from Ansell, please visit https://www.mscdirect.com/products/ansell-chemical.

Brought to you by Ansell

Ansell manufactures innovative products that provide unmatched quality, comfort and technology to millions of consumers, workers and first responders. All our gloves benefit from over 100 years of Ansell research and development, patented technology and state of the art manufacturing. Anywhere in the world Ansell helps workers finish their job more safely, more comfortably and more productively.

Related Articles

Worthy Waterproof Gloves You'll Want to Wear

![Why the Cheapest Safety Gloves Aren’t Always the Smartest [Infographic]](https://images.ctfassets.net/5j4ln2up7bt7/2gVEyRZylkBIlvTDtTRRc7/dde0c00e4846d6a88d56a7a68f09332a/mcr-PD5931_action4571-thumb.jpg)

Why the Cheapest Safety Gloves Aren’t Always the Smartest [Infographic]

Why Mental Health Belongs in Every Safety Conversation

Microfiber Tech: MFT PRO Gloves Pair Comfort and Performance