PROTECT WHAT MATTERS

PRO-SAFE® delivers personal protective solutions to keep your employees safe every day. They put their expertise into developing a full range of cut-resistant gloves engineered and manufactured to handle the toughest jobs.

THE RIGHT PROTECTION STARTS HERE

The U.S. Bureau of Labor Statistics reports that 30% of injured workers were wearing the wrong type of glove for the job. At PRO-SAFE®, they work with you to find the right combination of cut resistance, grip, dexterity, coverage, thermal protection and weight for your specific needs.

KNOW THE SCORE

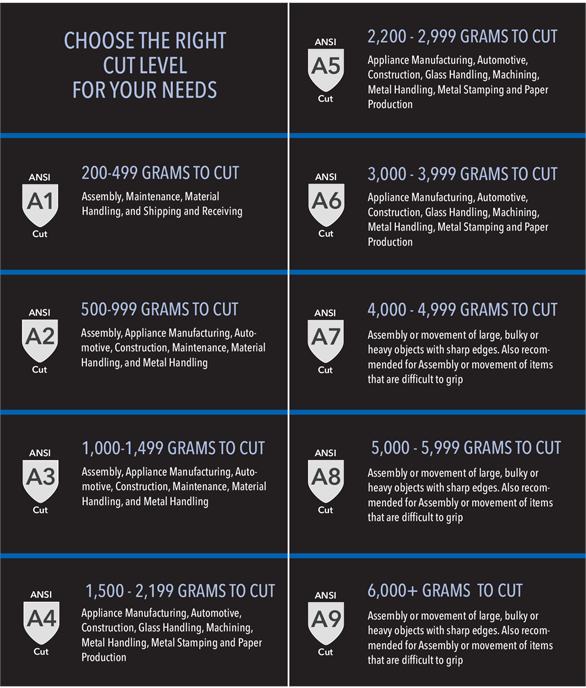

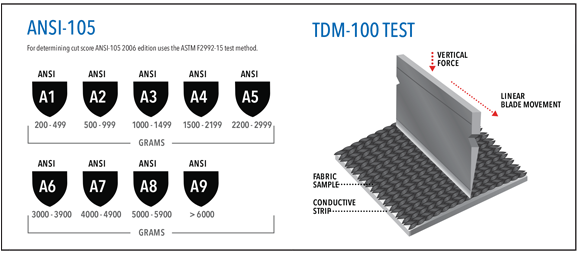

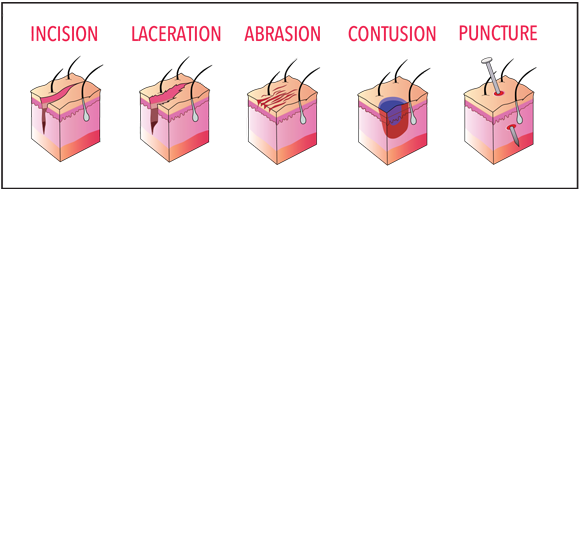

Here’s the key to knowing which gloves are right for which tasks: cut scores. These scores are based on two types of standard tests for abrasion, cut, tear and puncture protection. Although this testing is not mandated by the U.S. government, these are the industry standards that safety managers everywhere use to select cut protection gear.

LOOK AT YOUR PROCESS

Before choosing any gloves, conduct a comprehensive hand protection analysis in your facility, especially if your work environment:

Is a high-volume production with a variety of processes

Has high numbers of hand/finger-related injuries or skin disorders

Needs to reduce medical and indemnity costs associated with work time injury losses

Proper cut protection means understanding the cut risks of the job and different technology that is specifically designed for each task.

PRO-SAFE® cut-resistant gloves are tested to the latest ANSI standards for abrasion, cut, tear and puncture. The new ANSI cut levels make it easier to select the exact glove you need.

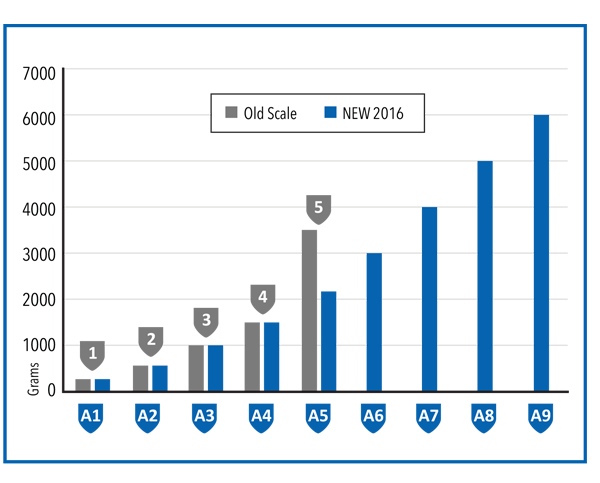

OLD VS. NEW CUT LEVELS BY GRAMS

U.S. BUREAU OF LABOR STATISTICS REPORT

111,000 lost-time hand injuries annually

Hand injuries send over one million workers to the emergency room each year

– 70% of injured workers were not wearing gloves

– 30% did wear gloves, but had inadequate, damaged or the wrong type of glove for the job

The average hand injury medical claim has now exceeded $6,000, with each lost-time workers’ compensation claim reaching nearly $7,500*

*According to BLS and National Safety Council

ASK THE EXPERTS

Working with safety industry experts at PRO-SAFE® is a critical part of developing proper protocols and ensuring that your employees have the right level of cut protection for each job.

UNDERSTANDING YOUR RISK

When evaluating how much cut protection you need, start with asking the right questions about the risk of hand/finger-related injuries in your facilities.

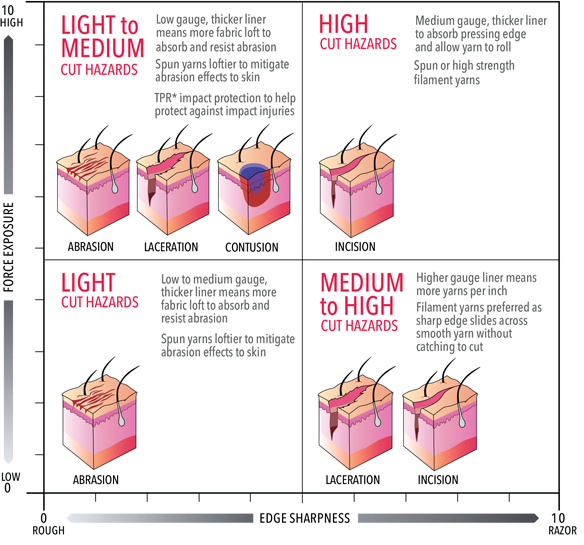

Different fabrics are designed to protect against different types of cut risks.

CUT RISK HAZARD MATRIX

QUESTIONS TO CONSIDER

How much do hand injuries and occupational skin diseases cost your plant? In money? Lost time?

Is your current hand protection addressing all of your application requirements in a cost-effective manner? Are all of your processes accounted for?

Have the OSHA-reportable injuries and non-reportable hand injuries been evaluated and costs determined by each individual department in your plant?

Has your plant management and a glove safety professional examined your entire work environment? Walking through the answers to the first three questions with a dedicated safety professional can make all the difference.

WHAT CUT SCORES MEAN TO YOU

The difference between a non-reportable injury (small cut) and a reportable one is only a fraction of a gram of force, making the right cut protection level absolutely critical.

PRO-SAFE® scores are determined by both ANSI-105 (the industry standard in the U.S.) and EN 388 (European) testing standards. The ANSI-105 testing method combines vertical edge force with linear blade movement to provide cut protection levels from A1 (lightest cut protection) to A9 (most cut protection).

Consider the type of injury risk to help determine the right glove for each task.

For more information about selecting the correct hand protection, and to view the PRO-SAFE® product line, visit MSCDirect.com.

![Why the Cheapest Safety Gloves Aren’t Always the Smartest [Infographic]](https://images.ctfassets.net/5j4ln2up7bt7/2gVEyRZylkBIlvTDtTRRc7/dde0c00e4846d6a88d56a7a68f09332a/mcr-PD5931_action4571-thumb.jpg)