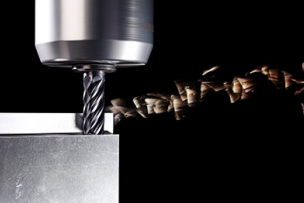

Shortened tool life, poor surface finish and built-up edge are common challenges when machining cobalt alloys. These tips can help you overcome them.

Kennametal Inc. has announced that its HARVI™ solid carbide end mills will be included as a preferred product in Lockheed Martin’s internal machining guide.

In automated machining for aerospace, one particular challenge is deburring the intersection of cross-drilled holes frequently found in engine components.

Seco Tools can help you optimize blisk manufacturing with better tools and strategies.

Advanced capabilities of multi-sensor capable coordinate measuring machines are helping aerospace manufacturers better meet production and quality goals with lower cost.

A new range of torque wrenches and in-house torque testing and calibration solutions from PROTO help reduce aircraft maintenance costs.

More efficient engines; lighter but stronger new materials–the aviation industry’s transition to sustainability will test aircraft manufacturers’ abilities to the full.

MicroSol® 692XT from Master Fluid Solutions utilizes the latest technology in metalworking fluid, specifically designed for the ultimate performance in demanding, multi-metal production environments.

In this short video, Sandvik demonstrates the CoroMill® MH20, their high-feed milling solution optimized for pocketing.

.jpg.png?itok=HAKhUOLU)