Castrol SmartControl measures metalworking fluid conditions from pH levels to concentration and temperature to help customers achieve peak cutting tool performance.

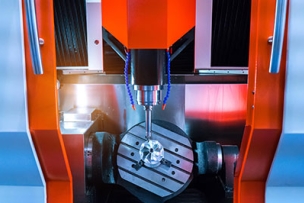

With more powerful milling tools available today than ever before, the big question facing machinists is how best to combine them to increase productivity, reduce cycle times, and improve tool life and surface finish.

For machinists drilling holes into oblique or curved surfaces, Guhring’s RT 100 FB can replace as many as three tool changes and setups required with other tools.

There’s more to choosing the best end mill than its price tag and availability.

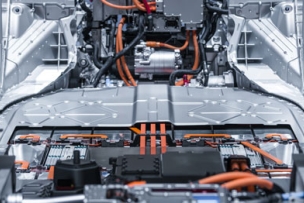

Some parts of electric vehicle production require a different toolbox than the building of their gasoline-powered predecessors. Kennametal has tools for all of them—including custom models created with 3D printing technology.

From joint replacements to scanning devices, modern medicine relies on state-of-the-art machining, durable metals that are tough to cut and shape and compliance with exacting specifications. Here’s how to cope with the challenges.

Working with tungsten is never easy, but these tips can help machinists complete a workpiece successfully.

New metalworking fluids can help machine shops improve productivity and cut costs. Which one is right for your shop?

The technological advances that power Industry 4.0 can also enable the use of predictive analytics to help manufacturers prevent accidents rather than investigating what went wrong afterward.

Here are seven steps machine shops and metalworking businesses can take to reduce the risk of costly stockouts.