In response to growing demand for electric vehicle (EV) manufacturing, cutting tool providers are developing new designs, geometries, substrates and coatings that will benefit the machining market. Here are three advances.

Three cutting tool experts explain why machining times are often longer than they should be and what you should do about it

Presetting outside the machine tool allows the machine tools to be running, while the tool assemblies are being set-up as back-ups or for the next job.

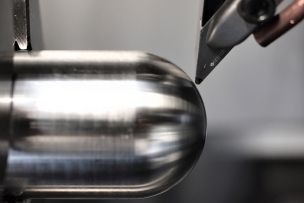

For manufacturers willing to make the investment, circle segment cutting can reduce cycle times and increase tool life of certain CNC jobs. Here’s what you need to know.

Sandvik introduces the CoroMill® MH20, a high-feed milling solution.

Your spindle is the heart of your machine. Precision Drive Systems details the signs that your spindle is failing.

In this short video, OSG discusses the importance of feed rate when drilling.

Sumitomo’s binderless CBN and PCD help machinists increase speed and efficiency.

Kennametal has introduced a new line of PCD round tools for aluminum machining that delivers up to 10 times higher productivity than carbide tooling.

In this video, Renishaw discusses automation in a CNC manufacturing environment and how the factory of the future will need to go beyond mechanical automation to deliver the productivity benefits and provide a platform for sustainable manufacturing.