Arc Flash Labeling Requirements

How to Properly Label Your Equipment to Meet NFPA 70E.

How to Properly Label Your Equipment to Meet NFPA 70E.

Six Primary Responsibilities that Facilities Must Meet.

What Equipment Requires An Arc Flash Label?

Seven Elements of an Arc Flash Label.

The National Fire Protection Association (NFPA) details how to comply with the Occupational Safety and Health Administration's (OSHA) regulation, 29 CFR 1910.333(a), through the NFPA 70E standard.

According to the NFPA 70E standard, there are six primary responsibilities that facilities must meet. These responsibilities include:

Training for employees

Written safety program in place that is actionable

Personal Protective Equipment (PPE) available for employees

Insulated tools

Arc flash hazard degree calculations

Properly labeled equipment

Arc flash labeling is the responsibility of the employer, not the manufacturer or installer of the equipment. Labeling is required for any piece of electrical equipment that may need examination, adjustment, service or maintenance while energized, creating the potential for an arc flash incident to occur.

In order to comply with the label requirement of NFPA 70E, your team should understand what electrical equipment needs to be properly labeled for arc flash.

Here are a few examples of locations an arc flash label should go.

Ideal for un-terminated wires or cables needing superior abrasion and chemical resistance.

Ideal for general marking of terminated or unterminated cables and wires that may be curved or become curved.

Ideal for terminated cables or wires that may need additional abrasion or chemical resistance.

Ideal for getting larger amounts of data on small diameter wire and cables such as fiberoptic cables.

Ideal for multi-conductor cables or bundled wires/cables.

Ideal for multi-conductor cables or bundled wires/cables.

Now that you’re familiar with the equipment that needs labeling, here are the elements you will need to include in your arc flash label.

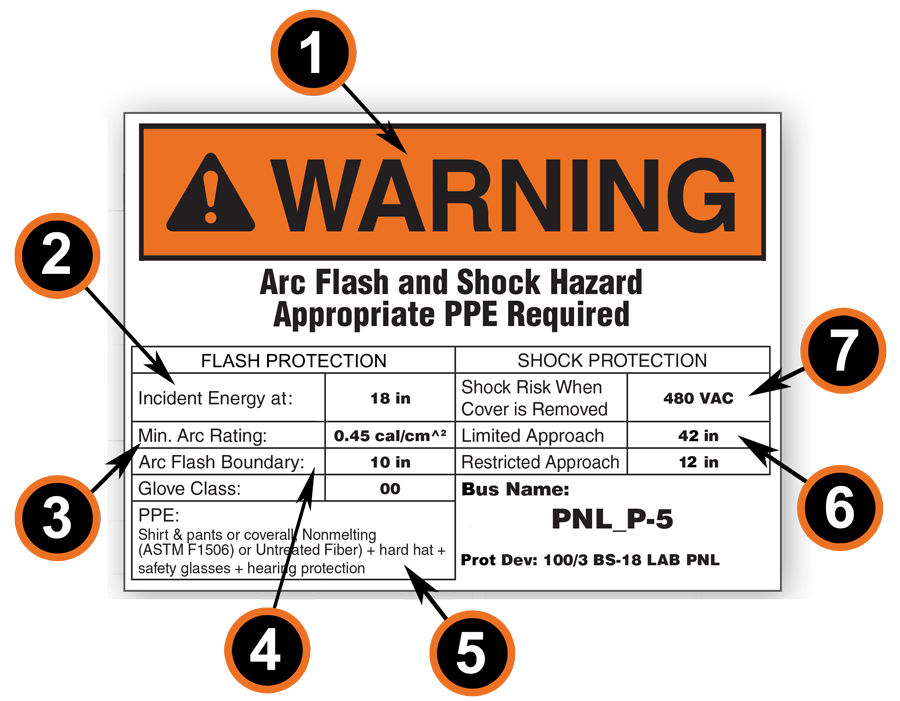

1 - Danger or Warning header. A common guideline is to use the "Danger" header when the voltage is over 600 or when the incident energy is over 40 cal/cm2. If it is less than this threshold, an orange "Warning" header is typically used.

2 - “Incident Energy at” is the corresponding working distance. The Institute of Electrical and Electronics Engineers (IEEE) defines this as, “the dimension between the possible arc point and the head and body of the worker positioned in place to perform the assigned task.”

3 - “Min. Arc Rating” is the incident energy. A measurement in calories/cm2 or Joules/cm2 of thermal energy at a working distance from an arc fault.

4 - Arc Flash Boundary. This is the shortest distance at which a person working at the time of an arc-flash may receive permanent injury (the onset of a second degree burn or worse) if not properly protected by flame-resistant (FR) clothing.

5 - Personal Protective Equipment (PPE). Each hazard risk category requires a different level of protection. Categories range from 1 to 4. Category “0” was removed in the NFPA 70E 2015 Changes.

6 - “Limited Approach” and “Restricted Approach” fields are related Shock Hazard Approach Boundaries. These boundaries are defined in more detail in our Arc Flash Workplace Safety Guide. The “prohibited approach” boundary was removed in the 2015 NFPA 70E edition.

7 - “Shock Risk When Cover is Removed”. The voltage of the equipment.

Previously Featured on Brady's website.

Brady SPC has been successfully developing, manufacturing and shipping absorbent products for nearly 40 years. Throughout the decades, their customers have relied on SPC products to help them prevent slips, trips and falls within their facilities. Absorbents and spill control products are its focus. Brady SPC has invested in its people, processes and facilities to ensure that it provides their customers with the best products for all their spill control needs.

![Why the Cheapest Safety Gloves Aren’t Always the Smartest [Infographic]](https://images.ctfassets.net/5j4ln2up7bt7/2gVEyRZylkBIlvTDtTRRc7/dde0c00e4846d6a88d56a7a68f09332a/mcr-PD5931_action4571-thumb.jpg)