Arc Flash Safety Checkup

Establish a safer, more compliant electrical safety program.

Establish a safer, more compliant electrical safety program.

To help you establish a safer, more compliant electrical safety program, Brady’s electrical engineers target and evaluate key areas covered under the 2015 NFPA 70E Standard. Take a look at the following questions to determine your progress and tasks needed to help mitigate electrical risks and continuously improve your current state.

YES — Under NFPA 70E, Arc Flash Risk Assessments must be:

Reviewed periodically at minimum every 5 years

Updated when a major modification or renovation takes place

NO — NFPA 70E Requires that an Arc Flash Risk Assessment be performed and shall:

Determine if an arc flash hazard exists. If it does exist, the risk assessment will determine appropriate safe-related work practices, arc flash boundary and PPE to be used within the arc flash boundary.

The results of the risk assessment must also be documented.

YES — NFPA 70E 110.6(E) requires that all training must be documented and employees must show proficiency. NFPA 70E 110.2(D) requires employees to be given additional electrical safety-related work practices every three years. Employees must be retrained before performing any tasks that are performed less often than once per year. And Article 100.6 (D)(3) requires that an employee must be retrained or receive additional training:

If the supervisor observes, or annual inspections reveal, that the employee is not following the rules and regulations.

If new technology, new types of equipment or changes in procedures necessitate the use of safety-related work practices that are different from those the employee would normally use.

If the employee must use safety-related work practices that are not normally used during his or her regular job duties.

NO — NFPA 70E 110.2(D) requires employees to be given additional electrical safety-related work practices every three years. Employees must be retrained before performing any tasks that are performed less often than once per year. And Article 100.6 (D)(3) requires that an employee must be retrained or receive additional training:

If the supervisor observes, or annual inspections reveal, that the employee is not following the rules and regulations.

If new technology, new types of equipment or changes in procedures necessitate the use of safety-related work practices that are different from those the employee would normally use.

If the employee must use safety-related work practices that are not normally used during his or her regular job duties.

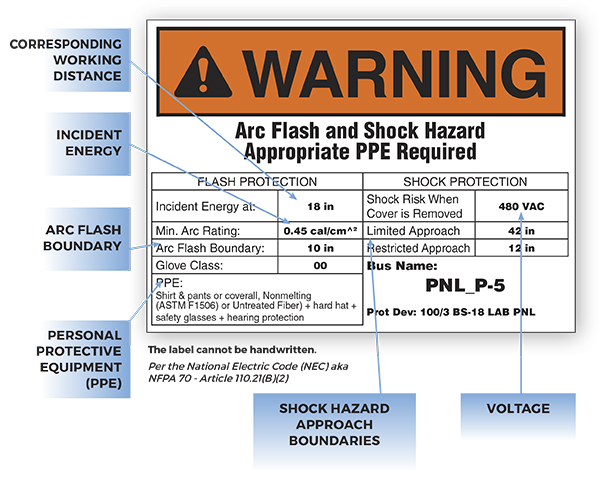

When looking at your best practice label you should see:

Incident energy and corresponding working distance

Arc flash and shock hazard boundaries

Device name

Level of PPE

Nominal system voltage

Anything above 50V that could be worked on while energized, resulting in exposure to electrical hazards, requires an arc flash label.

Visit BradySafety.com for more information.

Brady SPC has been successfully developing, manufacturing and shipping absorbent products for nearly 40 years. Throughout the decades, their customers have relied on SPC products to help them prevent slips, trips and falls within their facilities. Absorbents and spill control products are its focus. Brady SPC has invested in its people, processes and facilities to ensure that it provides their customers with the best products for all their spill control needs.

![Why the Cheapest Safety Gloves Aren’t Always the Smartest [Infographic]](https://images.ctfassets.net/5j4ln2up7bt7/2gVEyRZylkBIlvTDtTRRc7/dde0c00e4846d6a88d56a7a68f09332a/mcr-PD5931_action4571-thumb.jpg)