The Benefits of Coolant-Through End Mills

KYOCERA SGS Precision Tools announces a large expansion of the popular H-Carb seven-flute high efficiency end mill series with over 400 new coolant-through options.

KYOCERA SGS Precision Tools announces a large expansion of the popular H-Carb seven-flute high efficiency end mill series with over 400 new coolant-through options.

KYOCERA SGS Precision Tools announces a large expansion of the popular H-Carb seven-flute high efficiency end mill series with over 400 new coolant-through options.

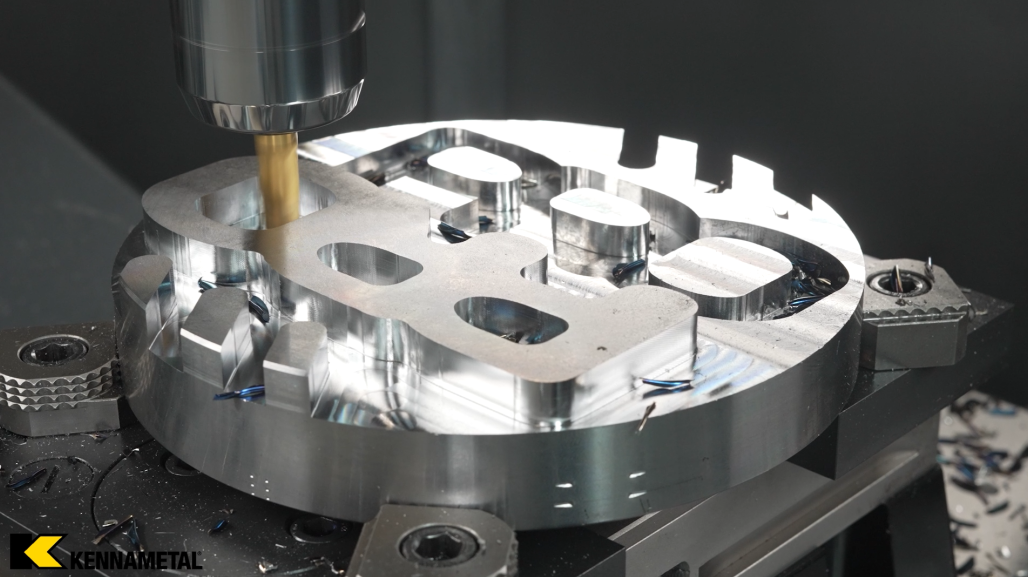

Available in various lengths of cut, the new H-Carb Series 77 coolant-through end mills specialize in deep axial trochoidal and high-speed machining applications. The new coolant-through varieties offer better wear, surface finish, and chip evacuation when pocketing or slotting. The H-Carb’s specially designed core and flute design improve rigidity and chip flow while reducing deflection. The seven-flute design allows for superior finishes at higher speed and feed rates versus 5 and 6 flute tools.

The expanded H-Carb portfolio features specialized Ti-NAMITE®-A or Ti-NAMITE®-M coating technology for increased wear and abrasion resistance extending tool life dramatically to tackle a wide range of materials and applications. The Chip Breaker profile is standard option with a wide range of square end and corner radii options offered to meet a variety of machining specifications.

Heavy-duty core and specialized flute design for improved rigidity, chip flow and reduced deflection

Chip Breaker profile standard in portfolio and aids in chip flow, especially in deep pocketing operations

Deep pocketing and slotting capability using various lengths of cut offered applying a trochoidal tool path

Coolant-through options available for better wear, surface finish, and chip evacuation when pocketing or slotting

CAM programming methods using high-efficiency machining by applying trochoidal tool paths and incorporating constant cutter engagement

Available in 3 lengths of cut (2.5xD, 3xD, 4xD)

Steel ≤ 45 HRc

Stainless Steel ≤ 45HRc

Cast Iron ≤ 45HRc

High-Temp Alloys

Titanium Alloys ≤ 45 HRc

Aerospace

Medical

Power Generation

Automotive

Mold & Die

Casting & Foundries

General Engineering

Previously Featured on KYOCERA SGS Precision Tools blog.

KYOCERA Precision Tools is a world-class manufacturer of indexable tooling solutions. At KYOCERA, we’re passionate about revolutionary cutting tool technology. We design and develop advanced indexable cutting tools that not only meet but exceed quality expectations, all while delivering the cost-efficiency that today’s metalworking professionals need to stay competitive in a variety of industries including, aerospace, automotive, medical, small parts, and mold & die