Case Study: Minimize Chipping with OSG’s PHOENIX® PD Indexable Drill

OSG uses its PHOENIX PD indexable drill to eliminate chipping and extend tool life for one heavy industry customer in this case study.

OSG uses its PHOENIX PD indexable drill to eliminate chipping and extend tool life for one heavy industry customer in this case study.

Upon review of the application it was determined the current drill design was causing the irregular chipping due to the variation of the placement of the cast holes. We recommended our PHOENIX PD indexable drill. By drilling with this indexable inserted drill, the drill will enter the part consistently even in offset holes.

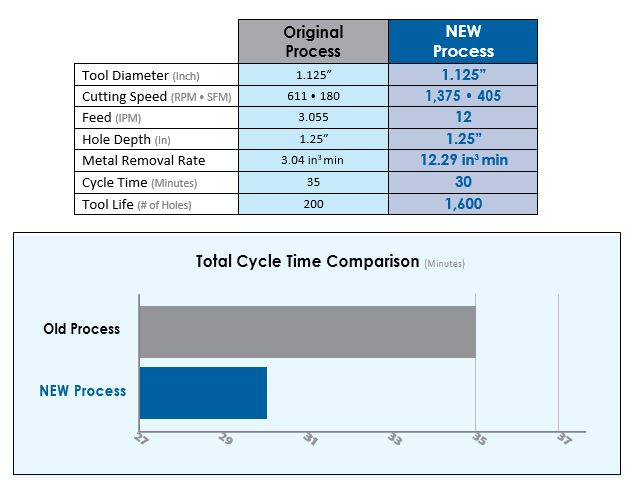

OSG was able to successfully achieve both goals. By eliminating the chipping, tool life was improved from 100 parts/head to 400 parts/index. We also were able to both increase the speed and feed, resulting in the cycle time to be reduced from 2,100 sec (35 min) to 1,800 sec (30 min).

Tool life improved from 100 parts/head to 400 parts/index.

Cycle time reduced from 35 min. to 30 min.

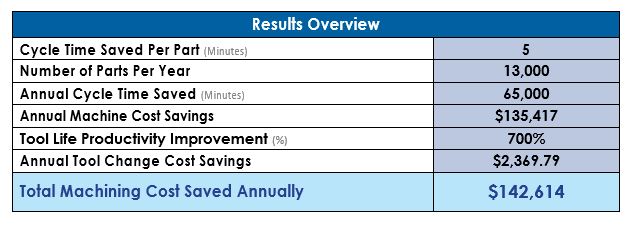

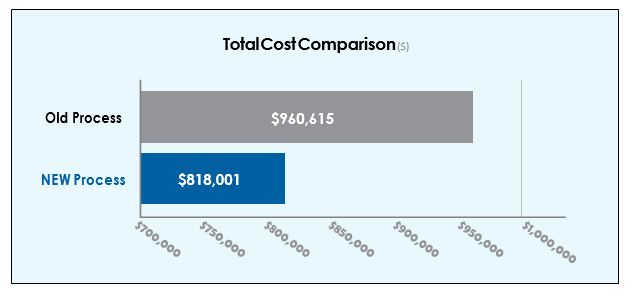

A total annual savings of over $140,000!

The customer was able to save roughly 1,000 total hours of machine time per year and decrease their insert usage from 130 heads/year to 16 inserts/year. In total customer was able to save over $140,000!

Download a PDF of the Case Study here.

Previously Featured on OSG's website.

OSG® is known worldwide for manufacturing premium round cutting tools for the metalworking industry. OSG remains focused on producing the highest quality and most consistent performing threading, drilling and milling tools. OSG provides a total solution of metalworking tools including spiral point taps, jobber length drill bits, square end mills, ball end mills and roughing end mills.