Factors In Glove Selection: Cut Protection

A Cut Protection Program is an important part of managing safety in your operation.

A Cut Protection Program is an important part of managing safety in your operation.

A Cut Protection Program is an important part of managing safety in your operation. Cut and abrasion risks are some of the most common workplace hazards that often lead to personal injuries. Safety managers need to be aware of current and pending regulations surrounding hand protection to insure workers are equipped with the proper PPE equipment. This guide serves as an overview of factors in the selection of the right glove in various risk environments.

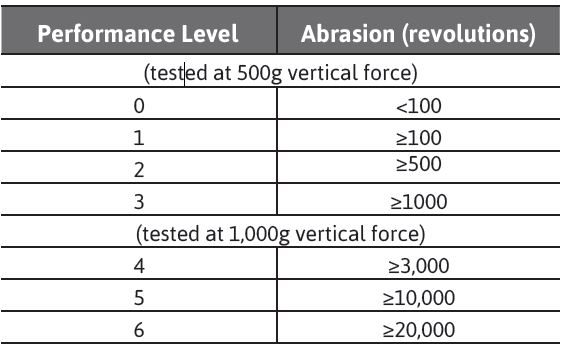

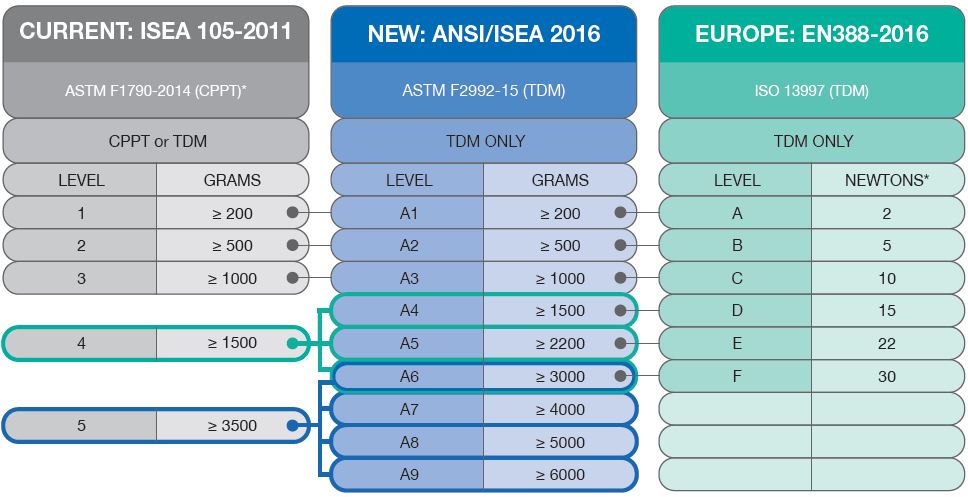

ANSI (American National Standards Institute) Cut and Abrasion Resistance tables help identify the level of resistance offered, enabling compliance with OSHA regulations 1910.38 (a) and 1910.38 (b) intended to mitigate risk of injury and increase worker productivity. The ANSI/ ISEA (International Safety Equipment Association) 105-2005 standard provides a consistent, numeric-scale method to rate products in designated areas.

These new standards include changes to the ratings scale and the standardization on a testing methodology.

Glove manufacturers have developed a range of educational tools to make the standards simpler to understand and easier to adopt. In addition, their gloves that offer cut protection should be marked per the new performance standards to ensure full adherence.

will communicate 2016 ANSI cut levels in new graphic icons,

as shown on the glove example below.

Ansell manufactures innovative products that provide unmatched quality, comfort and technology to millions of consumers, workers and first responders. All our gloves benefit from over 100 years of Ansell research and development, patented technology and state of the art manufacturing. Anywhere in the world Ansell helps workers finish their job more safely, more comfortably and more productively.

![Why the Cheapest Safety Gloves Aren’t Always the Smartest [Infographic]](https://images.ctfassets.net/5j4ln2up7bt7/2gVEyRZylkBIlvTDtTRRc7/dde0c00e4846d6a88d56a7a68f09332a/mcr-PD5931_action4571-thumb.jpg)