H-Carb End Mills Case Studies & Videos

KYOCERA SGS employed its new 7 flute Series 77 H-Carb end mill in two different case studies.

KYOCERA SGS employed its new 7 flute Series 77 H-Carb end mill in two different case studies.

In two different case studies, KYOCERA SGS Precison Tools (KSPT) employed its new 7 flute Series 77 H-Carb end mill to reduce job cost by increasing tool life, reducing machining time, and improving manufacturing efficiency.

The goals of this study were to significantly reduce job cost through increasing tool life, reducing machining time and improving manufacturing efficiency when machining 718 Inconel.

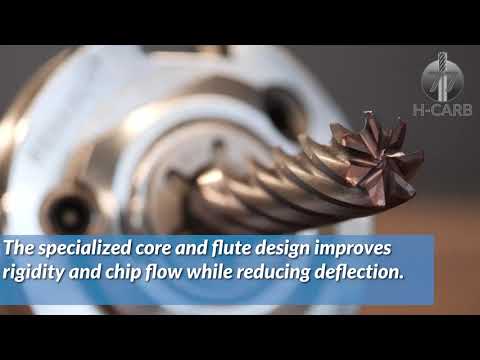

KSPT approached this job with the new 7 flute Series 77 H-Carb high-efficiency end mill. Due to the specialized core and flute design which improves rigidity and chip flow while also reducing deflection, the H-Carb was able to capacitate higher speed and feed rates, while still producing optimal part finish.

Nickel-based alloys are known to be difficult to machine, due to low thermal conductivity and chemical reactivity with tool material at high temperatures. They are also known to have a high hardness and low elastic modulus. The new series 77 H-Carb high-efficiency end mill with its Ti-Namite®-A coating was the perfect tool to apply to this job. The speed and feed that the H-Carb was able to capacitate was 49% higher and the feed rate was increased by 276% over the competitor's end mill.

These efficiencies lead to a 575% improvement in material removal rate. The cycle time was reduced from 30 minutes to just over six minutes. The H-Carb produced four times as many parts per new tool. All these performance capabilities combined to produce a machining cost reduction of over $10,000. When that amount is combined with the amount saved via the smaller number of new tools needed, you get a total savings of $22.495.75.

Read the complete Case Study to see how the 77 H-Carb stacked up against the competition.

See the H-Carb end mill in action in this short video:

The goals of this study were to reduce job cost when machining stainless steel through a complete revision of the manufacturer's strategy. In doing so, KSPT looked to increase tool life, reduce machining time, and provide an improvement in manufacturing efficiency.

For this job KSPT picked the Series 77 H-Carb, 7 flute high-efficiency end mill, and attempted a single-axial stepdown. A specialized core and flute design improves rigidity and chip flow, while also reducing deflection, making the H-Carb well suited for deep axial cuts.

The improved cycle time that the H-Carb was able to facilitate was more than 3 times faster, and the feed rate was almost 5.5 times higher than the competitor's indexable cutter. These efficiencies lead to a 1,460% improvement in material removal rate. The H-Carb produced almost 4 times as many parts per new tool.

Read the complete Case Study to see how the 77 H-Carb helped this aerospace manufacturer realize a machining cost reduction of over $113,000.

Watch this video to see how the Series 77 H-Carb performs in a trochoidal slotting application.

Previously Featured on Kyocera SGS Precision Tools' YouTube channel.

Go to MSCDirect.com to find the H-Carb high-efficiency end mill that's right for your application.

KYOCERA Precision Tools is a world-class manufacturer of indexable tooling solutions. At KYOCERA, we’re passionate about revolutionary cutting tool technology. We design and develop advanced indexable cutting tools that not only meet but exceed quality expectations, all while delivering the cost-efficiency that today’s metalworking professionals need to stay competitive in a variety of industries including, aerospace, automotive, medical, small parts, and mold & die