High-Dexterity Work Gloves: How the Right Pair Empowers Precision and Protection

Ansell’s HyFlex™ Precision Comfort Series with AEROFIT™ Technology enhances tactility and sensitivity while ensuring a more comfortable and breathable glove feel.

Ansell’s HyFlex™ Precision Comfort Series with AEROFIT™ Technology enhances tactility and sensitivity while ensuring a more comfortable and breathable glove feel.

Workers are expected to handle small components with speed and precision, yet their safety gear can sometimes get in the way. And too often, employers must choose between the protection that keeps workers safe and the dexterity that lets them work efficiently.

“It’s one thing to provide a glove, but if it’s too bulky, so you don’t have the dexterity, you’re going to lose the efficiency,” says Jason Kokoszka, Ansell’s associate director of marketing for the mechanical portfolio in North America. “The worker is not going to get the job done on a timely basis. They’re going to get fatigued because the glove is so cumbersome. It’s a risk for musculoskeletal injury.”

Thankfully, precision safety gloves exist to eliminate that trade-off—empowering workers to stay both protected and productive.

Time and again, Ansell’s service staff hear from end users who are wanting to be as productive as they can be in their jobs, and needing a glove that’s thinner, lighter and more breathable in precision applications.

Knowing this problem facing these workers, Ansell went about creating a solution.

WATCH: Here’s what experienced workers think of Ansell’s HyFlex Precision Comfort Series gloves:

The glove-maker turned to its robust research and development team, comprising 18 R&D facilities around the world. “We have dedicated scientists who are looking at what the trends are and how we can meet user needs through technologies,” Kokoszka says.

“The last couple of years,” he adds, “the biggest trends we’ve been seeing are a need for something thinner and lighter but is going to that high level of protection, whether that’s cut protection, abrasion resistance or multi-hazard protections.”

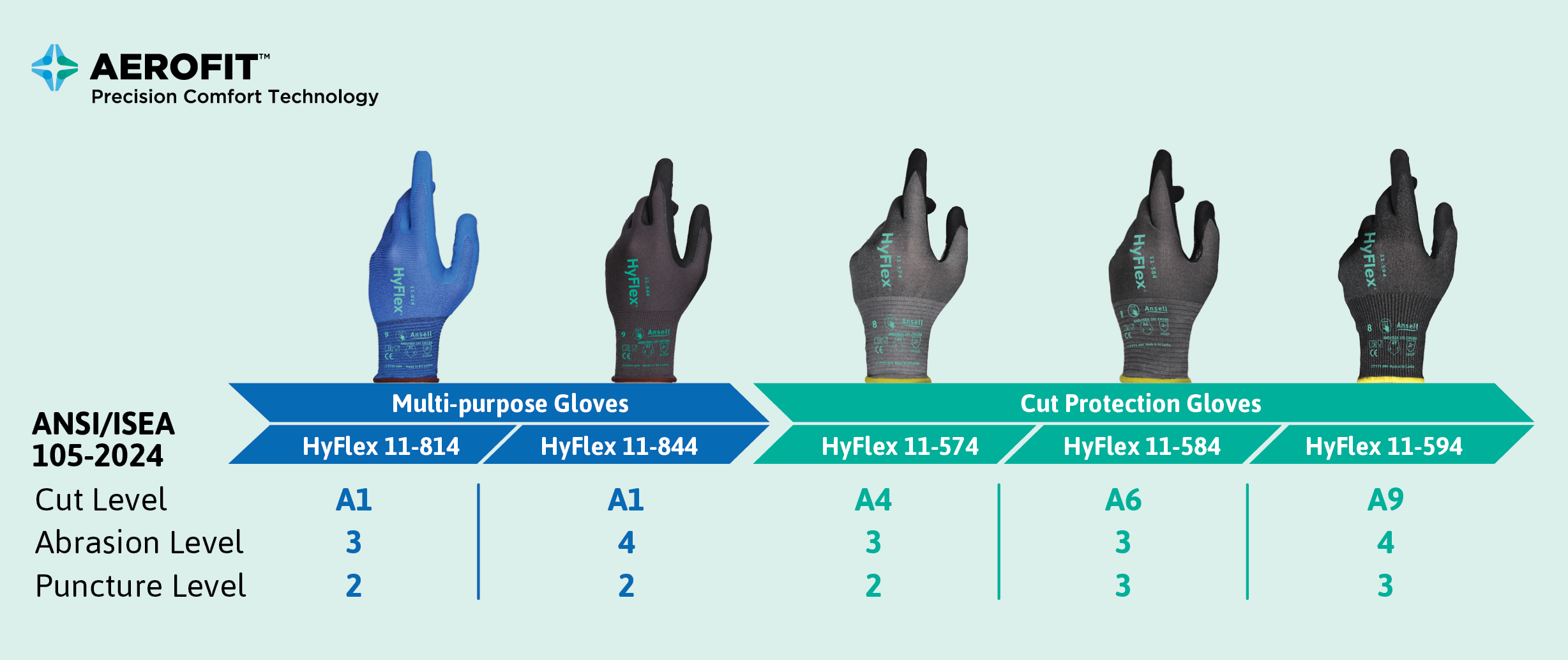

The quest for ultimate comfort and safety in precision applications resulted in the HyFlex™ Precision Comfort Series with AEROFIT™ Technology, which includes three cut-resistance gloves and two multipurpose gloves.

“The new AEROFIT Technology features an innovative, highly flexible foam nitrile coating,” Kokoszka explains. “It’s formulated to improve tactility and sensitivity and provide comfort and breathability.”

Thanks to AEROFIT Technology, HyFlex Precision Comfort Series gloves are 20 percent lighter, 30 percent thinner and 40 percent more flexible compared with the HyFlex Ultra Lightweight Series with FORTIX™ Technology.

What’s more, he says, “we’ve seen that it allows users to complete their precision tasks up to 42 percent faster.” The results were based on a survey of 52 wearers comparing Ansell HyFlex 11-574 gloves to competitive gloves available on the market in May 2025.

“They’re getting the protection they need, but at the same time, they’re going to have that comfort, tactility and precision to be able to get the job done effectively,” he says.

“Having that thinner profile from a coating and a liner standpoint, when they get matched together, it’s such a second-skin feel that you don’t even realize you’re wearing the glove.”

Read more: Disposable Gloves: 5 Tech Innovations to Get Your Hands On

All of the gloves in the series are touchscreen compatible, which is another feature that users have asked for, so workers don’t have to remove their gloves to operate devices, helping to avoid a compliance issue. “A couple of years ago, touchscreen compatibility was a luxury when it came to gloves,” Kokoszka says. “Now it’s a necessity.”

At the NSC Safety Congress & Expo in the fall, Ansell’s booth was busy with people trying on the glove to do precision challenges with small objects, and it was an aha moment for them. “You just see people’s faces light up,” Kokoszka recalls. “The reception has been fantastic.”

The HyFlex Precision Comfort Series features a range of gloves to suit a variety of needs in the workplace.

The HyFlex 11-594, for example, has an A9 cut-resistance rating and an abrasion level 4 for handling heavy metal parts with sharp, rough edges. Employers who need cut resistance but not necessarily A9 can choose from the HyFlex 11-584 (A6) and HyFlex 11-574 (A4).

For multipurpose jobs requiring the assembly of small parts and components, the HyFlex 11-844 features an abrasion level 4, and the HyFlex 11-814, an abrasion level 3.

Read more: What Are the Levels of Cut Resistant Gloves?

With so many options—even from one manufacturer—it can be hard to know which glove is the right one. Besides the HyFlex Precision Comfort Series, for instance, Ansell offers the HyFlex Ultra-Lightweight Series with FORTIX Technology for tasks involving repetitive, abrasive actions with heavy force or weight application.

That’s where a selector tool comes in handy. “Our AnsellGUARDIAN™ platform allows us to make the right recommendation for gloves,” Kokoszka says. “We’ve taken decades of data and our on-site field salespeople visiting key industries and knowing these applications. At the end of the day, it comes down to making sure that they have the proper gloves.”

Ansell manufactures innovative products that provide unmatched quality, comfort and technology to millions of consumers, workers and first responders. All our gloves benefit from over 100 years of Ansell research and development, patented technology and state of the art manufacturing. Anywhere in the world Ansell helps workers finish their job more safely, more comfortably and more productively.