Introducing the Seco JSE510 Series

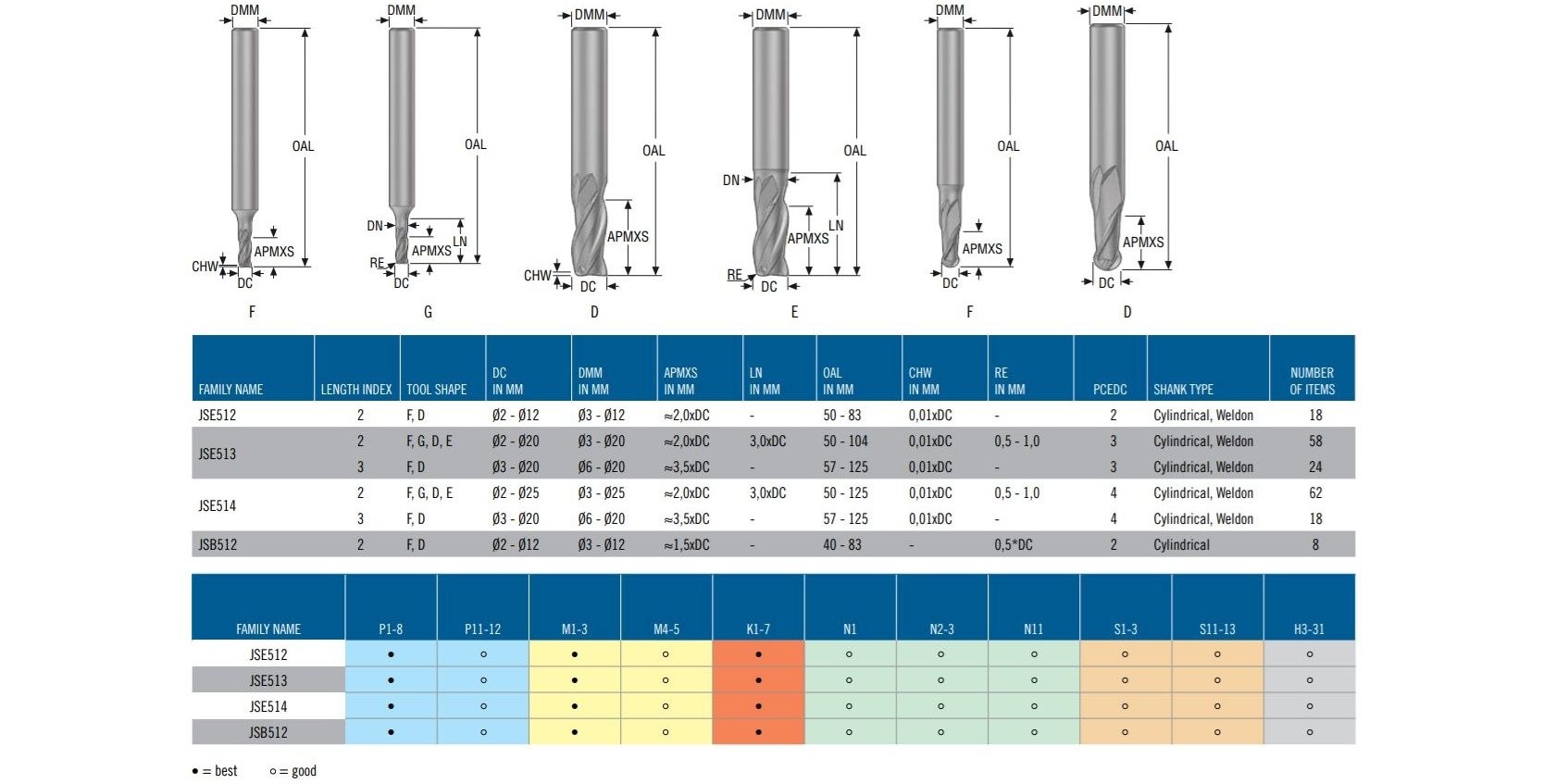

The new Seco JSE510 series is designed with four geometries and two length variants that give it well-optimized performance across virtually all milling applications.

The new Seco JSE510 series is designed with four geometries and two length variants that give it well-optimized performance across virtually all milling applications.

Achieve the lowest cost per meter in steels, stainless steels, cast iron, titanium and some aluminums with a single, well-optimized family of solid end mills: the Seco JSE510 series. Designed with four geometries and two length variants that give it well-optimized performance across virtually all milling applications, JSE510 end mills have the best-in-class tool life and stability today’s shops need.

Designed with irregular tooth pitch to allow increased speeds and feeds, a progressive helix, and an optimized high-cobalt carbide with SIRA coating, JSE510 solid end mills are built for stability and reliability. Two, three, and four-flute configurations and the JSB512 ball-nose geometry handle roughing and finishing for simple prismatic parts and complex 3D contours alike, including drilling, helical interpolation, ramping, full slotting, and side milling.

This helps your shop handle any job at the same time you cut back on the inventory required for flexible production. The long tool life is matched with high-rigidity geometries that can still perform even in less stable machining platforms. An optimized grade completes the package – and ensures reliable milling applications in virtually any steel, stainless steel, or titanium, as well as some aluminums and other materials.

See how SECO's JSE510 solid end mills can help you master your milling application in the short video below:

Seco Tools is your complete metalworking solutions provider offering cutting-edge, precision tools for indexable milling, solid milling, hole making, turning, threading, grooving and more. We’re proud to make for makers, invent for inventors, and partner with pioneers. In short - if the right tool for the job exists, we’ll deliver it. If it doesn’t, we’ll create it.