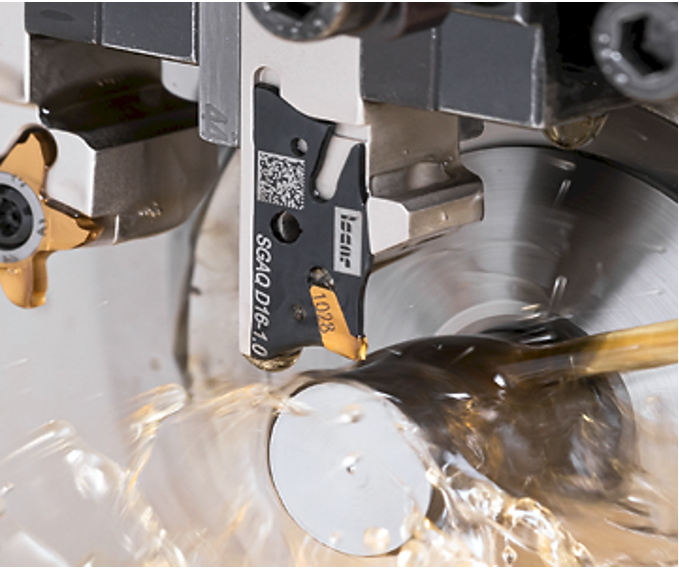

ISCAR SwissGrip – Narrow Parting for High Cost Savings on Swiss Machines

ISCAR’s new SwissGrip tooling system for Swiss machine parting is an innovative and economical system designed with raw material savings in mind.

ISCAR’s new SwissGrip tooling system for Swiss machine parting is an innovative and economical system designed with raw material savings in mind.

ISCAR’s new SwissGrip tooling system for Swiss machine parting is an innovative and economical system designed with raw material savings in mind. Due to high production in the Swiss industry, reducing the parting tool width increases the raw material savings. In addition, this new miniature blade system is designed for blade indexing within seconds, providing extremely short downtime when changing inserts. The system allows for 0.024” and 0.031” wide parting inserts up to 10 mm (0.393”) bar size. For bar sizes up to 16 mm (0.630”), the insert widths are 0.039” and 0.047”. All four blade/insert combinations fit the same shank, which is offered in both imperial and metric ranges from 0.375” to 0.625” and 10 mm to 16 mm.

What to look for: Machine shops making high volumes of small parts on swiss type machine tools. With the cost of materials increasing, the material savings from changing to a small width of cut part off insert can be significant. Less material removal and waste per part.

Watch this short video to learn more about ISCAR’s new SwissGrip tooling system:

ISCAR supports world class manufacturing through continual advances in cutting tools technology. ISCAR's comprehensive line includes indexable inserts, end mills, toolholders, solid carbide drills and more. With innovative machining technology, ISCAR's tooling solutions will reduce cycle times, increase machine tool capacity and improve the profitability of your machine shop.