ISCAR Turning, Grooving and Parting Tools for High Pressure Coolant

ISCAR JETCUT tools offer the ultimate solution for utilizing high pressure coolant (HPC) in a multitude of turning operations.

ISCAR JETCUT tools offer the ultimate solution for utilizing high pressure coolant (HPC) in a multitude of turning operations.

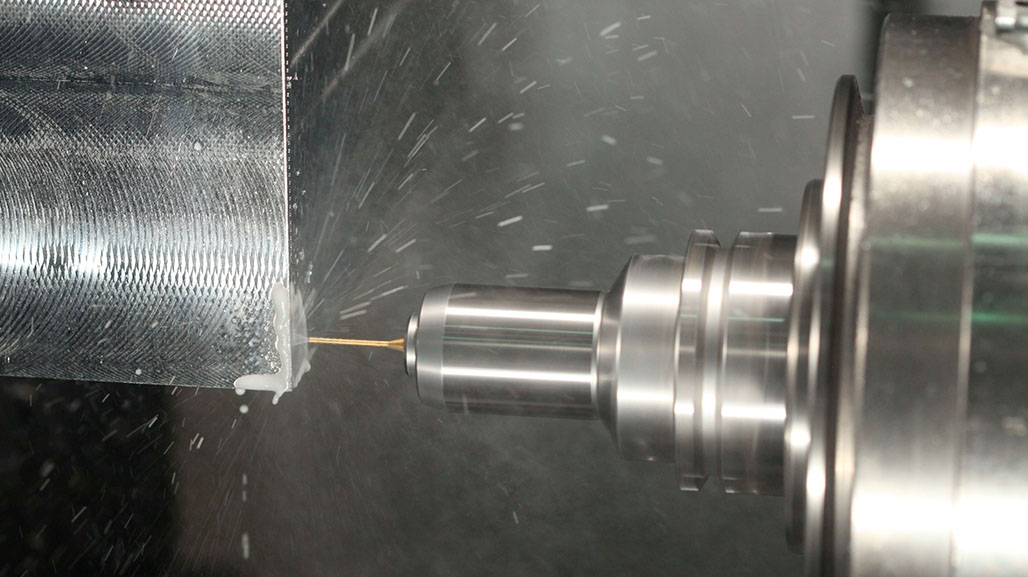

ISCAR JETCUT tools offer the ultimate solution for optimizing coolant flow and pressure, especially high-pressure coolant (HPC) in a multitude of turning operations. With the availability of high-speed machines which offer standard or optional 70-bar coolant systems and through-spindle coolant delivery, HPC technology has grown much more accessible and ISCAR provides hundreds of standard and special HPC turning tools for a wide range of applications. HPC has proven itself in dedicated turning applications on difficult-to-machine materials such as titanium and Inconel, increasing material removal rates at up to three times more than that of the conventional flood coolant system. Users report elimination of chip jamming, faster cutting and significantly longer tool life in outer and inner diameter turning as well as grooving, parting and hole making. The advantages of ISCAR’s JETCUT line are also noticeable when machining steel parts, where the chips are more manageable and insert life is significantly improved.

Watch JETCUT in action in this short video.

No transcript for this video - music only.

ISCAR supports world class manufacturing through continual advances in cutting tools technology. ISCAR's comprehensive line includes indexable inserts, end mills, toolholders, solid carbide drills and more. With innovative machining technology, ISCAR's tooling solutions will reduce cycle times, increase machine tool capacity and improve the profitability of your machine shop.