ISCAR’s Jet High Pressure (JHP) Coolant Tooling

ISCAR’s Jet High Pressure (JHP) coolant tooling—particularly its JETCUT product lines—drastically improves turning applications involving the use of coolant.

ISCAR’s Jet High Pressure (JHP) coolant tooling—particularly its JETCUT product lines—drastically improves turning applications involving the use of coolant.

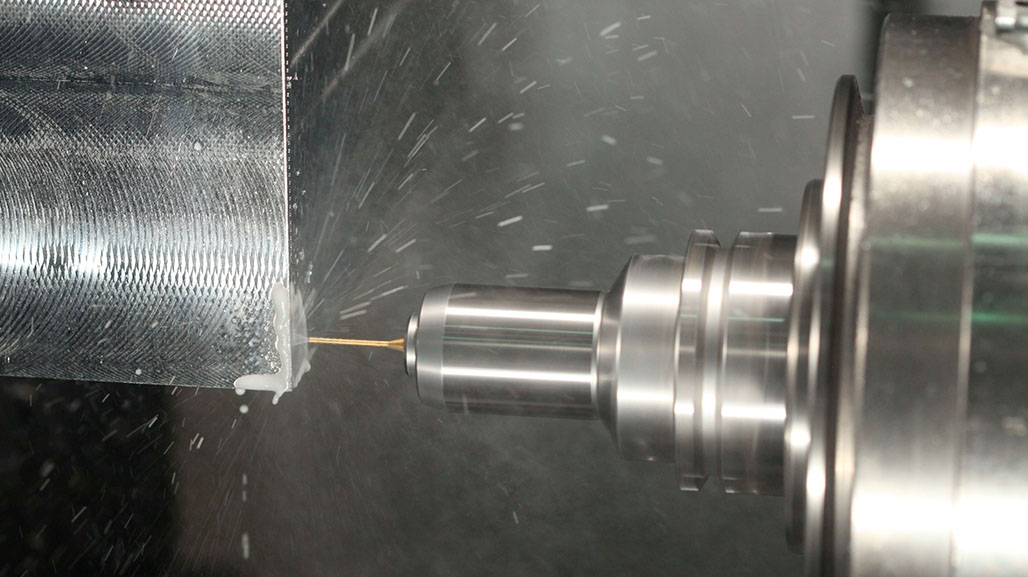

ISCAR’s Jet High Pressure (JHP) coolant tooling—particularly its JETCUT product lines—drastically improves turning applications involving the use of coolant. Designed to deliver coolant directly to the cutting zone at up to 70 bar of pressure, JHP tooling significantly improves heat dissipation and lubrication while typically allowing for increased cutting speeds to be applied (i.e., increased productivity). It’s important to note that turning applications on machines with standard/lower coolant pressure can also benefit from the optimized coolant delivery afforded by JHP tooling.

When compared with conventional flood coolant delivery in applications involving difficult-to-machine ISO M & S material groups (PH Stainless, Titanium, Inconel, etc.), JHP tooling significantly increases material removal rates, resulting in faster cycle times and reduced tool wear in all types of machining, especially in turning, grooving, and parting operations. The precision delivery of coolant has a quenching effect on molten chips, which helps with breaking them into manageable fragments to prevent chip jamming—a common issue in deep-parting/grooving applications or when dealing with interrupted cutting conditions.

ISCAR’s JHP tools also feature modular designs with multiple coolant inlet options, allowing flexible integration into various machines/setups. Their rigid overall design and clamping mechanisms ensure stability under extreme cutting conditions, further boosting machining reliability.

By optimizing thermal control and chip evacuation, ISCAR’s JHP tooling not only enhances productivity but also extends the lifespan of both tools and inserts. JHP tooling options offer a compelling solution for manufacturers seeking to push the limits of CNC machine utilization.

Browse mscdirect to search Iscar's JETCUT line.

ISCAR supports world class manufacturing through continual advances in cutting tools technology. ISCAR's comprehensive line includes indexable inserts, end mills, toolholders, solid carbide drills and more. With innovative machining technology, ISCAR's tooling solutions will reduce cycle times, increase machine tool capacity and improve the profitability of your machine shop.