Kennametal Award Winning 3D Printed Voith Tool

Kennametal Inc. recently announced that it has been named a winner of a prestigious R&D 100 Award for its innovative additive manufactured machining tool for large engine and transmission housings.

Kennametal Inc. recently announced that it has been named a winner of a prestigious R&D 100 Award for its innovative additive manufactured machining tool for large engine and transmission housings.

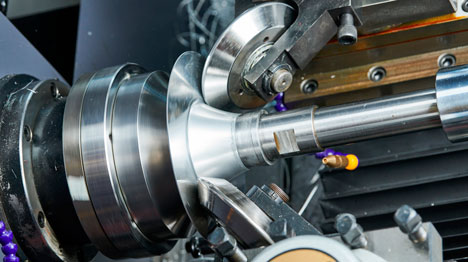

Kennametal Inc. recently announced that it has been named a winner of a prestigious R&D 100 Award for its innovative additive manufactured machining tool for large engine and transmission housings in transportation, including electric vehicles, made with new KENionic™ technology.

"This is an outstanding example of our industry-leading expertise in materials science, precision machining, bionics-inspired design and additive manufacturing that fuels Kennametal's innovation," said Dr. Carlonda Reilly, Vice President and Chief Technology Officer. "We welcome opportunities to leverage our core capabilities to continuously innovate for our customers and are thrilled our KENionic™ technology has been recognized with this award."

Developed to machine precision components for transportation applications, KENionic™ technology is part of a new class of Kennametal additive manufactured tools that feature an advanced design, with principles that mimic the most effective and efficient organic shape adaptations found in nature.

The tool is 50% lighter than conventional tooling and reduces machining time by approximately 50%, increasing productivity and efficiency for customers.

The R&D 100 Awards is the only science and technology awards competition that recognizes new commercial products, technologies and materials for their technological significance that are available for sale or license.

Previously Featured on Kennametal's News.

Kennametal brings together materials science, technical expertise, innovation and superior customer service to help the world fly, drive, power and build. Our tools, materials and wear-resistant solutions enable customers to run longer, cut faster and machine with greater precision across various industries from aerospace and defense, general engineering and transportation, to earthworks and energy. We don’t just make products, we deliver solutions.