National Manufacturing Day 2019: Closing the Skills Gap

There’s more to MFG Day than meets the eye.

There’s more to MFG Day than meets the eye.

Save the date: Oct. 4 is this year’s Manufacturing Day (MFG Day)—and there’s no shortage of preparation and excitement for educating and exposing future generations of workers to careers in manufacturing. We take the pulse of several regions in the U.S. to understand how MFG Day events are a catalyst to attract talent year-round.

Walmart, Stratasys, AK Steel and other companies of all sizes will participate in events for this year’s National Manufacturing Day (MFG Day), which is the first Friday of every October.

Whether hosting students at manufacturing plants or participating in a local event at a high school or college, MFG Day educates hundreds of thousands of students every year on the technologies and career paths available today—and in the near future.

In 2018, the National Association of Manufacturers estimated that MFG Day reached 200,000 students and parents through 2,100 events. Founding partner Fabricators and Manufacturers Association, International, started MFG Day in 2012. This year’s event is slated for Oct. 4.

“Manufacturing is a huge economic driver in Minnesota, employing more than 321,000 Minnesotans,” says Rich Garrity, Americas president of Stratasys, in a statement. “As the world’s premier 3D printing company, we’re working with leading manufacturers every day to reimagine how things are made … We are proud to support MFG Day, which showcases the diverse, high-paying careers our industry offers.”

To get a sense of what this year’s MFG Day will be like, we spoke with representatives from South Texas College, the Manufacturers Association of Central New York and Tooling U-SME.

One simple fact is hard to deny: A good portion of manufacturing workers are retiring or finding new jobs—and the loss of embedded knowledge is top of mind.

“As we all well know, the ‘silver tsunami’ is happening,” says Michele Clark, a senior marketing specialist for Tooling U-SME. “And new generations coming into the field are different and have different expectations and needs.”

More than one-third of respondents in Tooling U-SME’s 2018 “Industry Pulse: Manufacturing Workforce Report” stated that more than 20 percent of their workforce would be eligible for retirement in the next three years. The report also found 43 percent of manufacturers have annual turnover rates of 20 percent or higher.

It’s not surprising that 59 percent of companies cited the loss of knowledge as a serious challenge to overcome. The report’s authors advocate for the following:

“The transfer of incumbent knowledge must take place now. The status quo is no longer an option—structured programs that capture institutional knowledge are now a ‘must-have’ for manufacturers looking to grow their business.”

Tooling U-SME is not alone in its assessment of the job and employment landscape for manufacturing.

“Our employers are still suffering from the challenges that existed last year and the year before,” says Martha Ponge, director of apprenticeships at MACNY, the Manufacturers Association of Central New York. “We do not have enough middle-skilled workers to fill the number of job openings that exist in our community. We do not have enough entry-level workers coming in that will allow us to fill the pipeline.”

Want to learn about generational differences and how to work with them? Read “Charting Manufacturing Career Pathways for Gen Z and Beyond.”

In 2018, Clark led a MFG Day event for 70 students at East Tech High School in Cleveland. Clark organized a lunch-and-learn and a trade show at the school and brought in manufacturers and educators including 3D printing company MakerGear, Lincoln Electric and Cuyahoga Community College, known locally as Tri-C.

One of the lunch-and-learn speakers was Terrence Robinson, vice president of economic inclusion and early college early career pathways at MAGNET, or the Manufacturing Advocacy and Growth Network. During the trade show, students loved playing with the virtual welding system and helmet from Lincoln Electric.

“One of the other cool things we did was bring in The Rust Belt Welding Company, a local shop that got their training at Lincoln Electric but branched off and did their own thing making artistic fabrications from sheet metal,” Clark says. “And now their work is being featured throughout Greater Cleveland. They have bike racks, they have large structures and they do such cool stuff.”

Another benefit of showcasing a small shop like Rust Belt Welding is that students got to see an example of creative entrepreneurs who embody an independent spirit—and that not all careers in manufacturing are “9 to 5 on a shop floor,” Clark explains.

“These guys looked like the students: They had tattoos, they had bandanas, they drive motorcycles. They were very relatable for the students,” Clark says.

The result: Last year’s MFG Day event spurred the school to build a fabrication laboratory that now includes a CNC router, a laser engraver, a 3D printer, a large-format vinyl printer and cutter—and a virtual welding device.

Students are using these systems in their agriculture and culinary programs to 3D-print cookie cutters and to laser-cut boards outlining retail cuts of beef. They’re also building 3D-printed phone cases and learning about computer programming for a CNC. The school is launching an engineering program that will take full advantage of the fabrication lab.

“It has become a huge resource for East Tech High School to introduce their students to alternative career paths,” Clark says. “The bottom line is: MFG Day can make a difference.”

Are you where you want to be and earning what you want to make? Read “The State of Salaries and Hourly Pay in Manufacturing.”

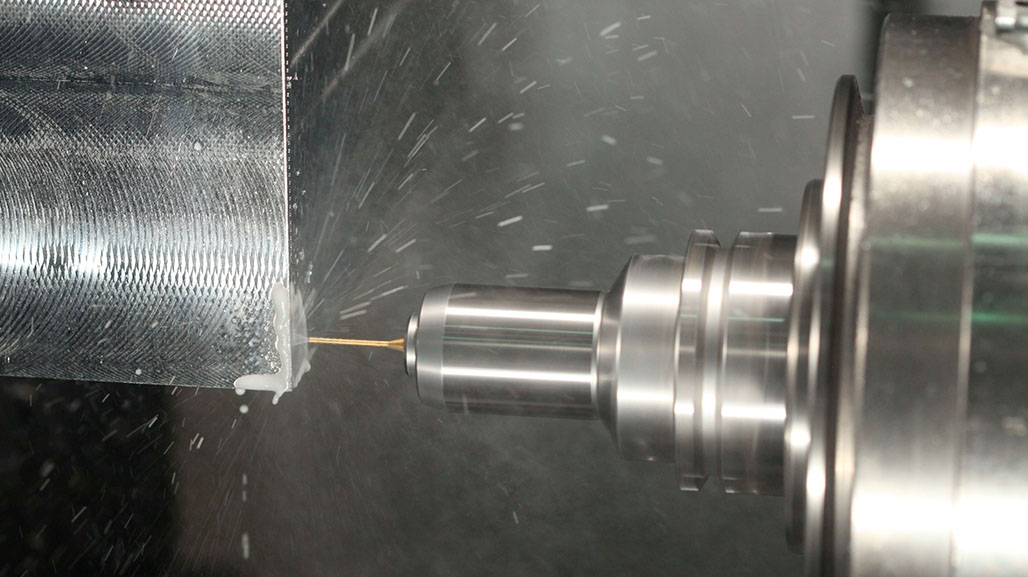

MFG Day spans the country and parts of Canada—and it exposes young minds to the ins and outs of today’s manufacturing, which uses many advanced machining technologies, tools and processes in clean, safe and often air-conditioned facilities, say industry advocates we spoke to recently.

There’s a pretty big event happening in central New York at Hill-Rom, formerly Welch Allyn, in Skaneateles Falls, New York. Here, 300 to 400 students will be bussed in from many regional school districts. Hill-Rom is a medical products manufacturer with offices all over the world.

MACNY is helping organize the event. The industry advocacy group also works with more than 40 companies in the region with apprentice and pre-apprenticeship programs. It has 150 students enrolled in apprenticeships today.

One new area being implemented is apprenticeships for information technology within aerospace and defense manufacturers such as Lockheed Martin. Griffiss Institute, formerly part of Griffiss Air Force Base, is a college participating in the apprenticeships, helping computer science graduates find work in regional businesses.

“This summer, we added 45 new apprentices in the area of IT, which was a new area of growth for us,” Ponge says. “They are software developers from Griffiss Institute, but they are looking for an added certification, which shows their capacity for working in a field, not just understanding and being able to program as per a college curriculum, but to do something that really has relevance to a particular business.”

Do you need a technical question answered? Ask the MSC Metalworking Tech Team in the forum.

South Texas College brings a unique perspective to MFG Day because of its proximity to the U.S.-Mexico border. South Texas College is about 10 miles from the border in McAllen, Texas.

“Here in the valley area in South Texas, there are a lot of manufacturing companies that work together with the maquiladoras from Mexico, and they assist in a lot of their production,” says Ivan Garcia, an instructor at the college who is leading this year’s MFG Day event. “We have companies that they work for aerospace, automotive, oil and gas, just about everything across manufacturing.”

A maquiladora in Mexico is a factory that operates under programs established and administered by the United States and Mexico. Materials, assembly components and production equipment used in maquiladoras are allowed to enter Mexico duty-free. Products made can be exported into the U.S. at lower tariffs than those from other countries.

“Our main goal with MFG Day is to open the doors for the community to see what’s really happening in the buildings nearby and to show them that we have the advanced manufacturing technology right here,” Garcia says. “We want to prepare students, and for them to say, ‘You know what? I don’t have to leave home and go work somewhere else. I have the opportunity right here in my community.’”

Like many states, Texas will pay for junior- and senior-level students to earn credits toward an associate degree in manufacturing while they are in high school—either by taking courses at South Texas College or others or by taking courses in their own high school labs and shops.

“For those students that earn their associates degree in manufacturing, we have a 98 percent placement rating with local companies,” Garcia says.

Students will be exposed to shops and companies that make parts for automotive, aerospace components, sheet metal, phone manufacturing, plastic injection and prototyping, Garcia says.

Garcia himself participated in MFG Day as a student, and he ended up getting a job at a local precision metalworking shop, Humanetics, that he visited during MFG Day.

This year’s event led by the Advanced Manufacturing Technology department will have 150 students from 11 school districts.

“There is opportunity. Right here,” Garcia says. “A lot of people, they think they have to migrate into the oil field industry, where they have to travel outside their hometown. We just want to let them know there is an opportunity for you to be home, stay with your loved ones and be here for them.”

Find a local shop participating in your area or learn how to host an event at your shop at MFGDay.com.

MFG Day is only one day a year, but activities to attract new talent to the industry are always going on. In fact, many companies and organizations that do not participate in MFG Day still make efforts to attract talent by being involved in their local schools and technical colleges, by hosting job fairs and by serving on boards that help institutions with accreditation.

“We are very well aware that one day out of the year is not going to change the perception of manufacturing,” says Martha Ponge of the Manufacturers Association of Central New York, or MACNY. “What we need to do is be in front of students and parents and educators all year long … We worked with 2,000 students, whether it was by inviting them to something like Manufacturing Day or participating in tech programs, going into schools and offering career coaching and tours of manufacturing facilities, or STEM programs for female students.”

MACNY is just one example of an active regional industry advocate. It has access to more than 300 manufacturers in its area and recently co-located with the local school boards association, so it has access to 50 school districts.

“I interact with the Utah Colleges of Applied Technology regularly,” says Reid Leland, founder and president of LeanWerks, a precision manufacturer in Ogden, Utah. “I sit on the advisory board and help them keep accreditation by giving them feedback about the industry. In this business, you have to be proactive. I give a recruiting presentation twice a year on what it’s like to be a machinist.”

Leland also participates in local STEM fairs and welcomes high school students and Scout troops into the company for tours and part-making demonstrations, usually in the spring and fall. LeanWerks gets tour requests from Job Corps at least twice a year—and usually has one or two Job Corps interns working for the company regularly.

LeanWerks markets its apprenticeship under its Technology Excellence Training (TExT) program to “avoid the dated connotation to old-school manufacturing associated with the word apprenticeship,” Leland says. The company emphasizes the ability to pursue “stackable” credentials offered by the Utah Colleges of Applied Technology and participating machine shops that can be transferred to Weber State University for credit toward a manufacturing engineering technology degree.

“One piece of advice for others: You can’t just appeal to the kids, you have to also appeal to the parents,” Leland says. “It’s hard.”

LeanWerks always invites parents to open houses and tours and speaks to them about the career stability, earning potential and job satisfaction that comes “with a career in machining for kids of the right ilk,” he says.

“Some of our top machinists make six figures a year without a college degree and student loan debt that often accompanies it—they are just great machinists,” Leland says.