The Mill 4™ Series

Learn more about the Mill 4 ™ Series. It's specially engineered to achieve excellent performance in regards to surface quality as well as higher metal removal rates in shoulder milling applications.

Learn more about the Mill 4 ™ Series. It's specially engineered to achieve excellent performance in regards to surface quality as well as higher metal removal rates in shoulder milling applications.

Engineered to achieve excellent performance in regards to surface quality as well as higher metal removal rates in shoulder milling applications.

The Mill 4 ™ Series offers solution for both low and high power machines.

“Stepless” solution for multiple-pass operations.

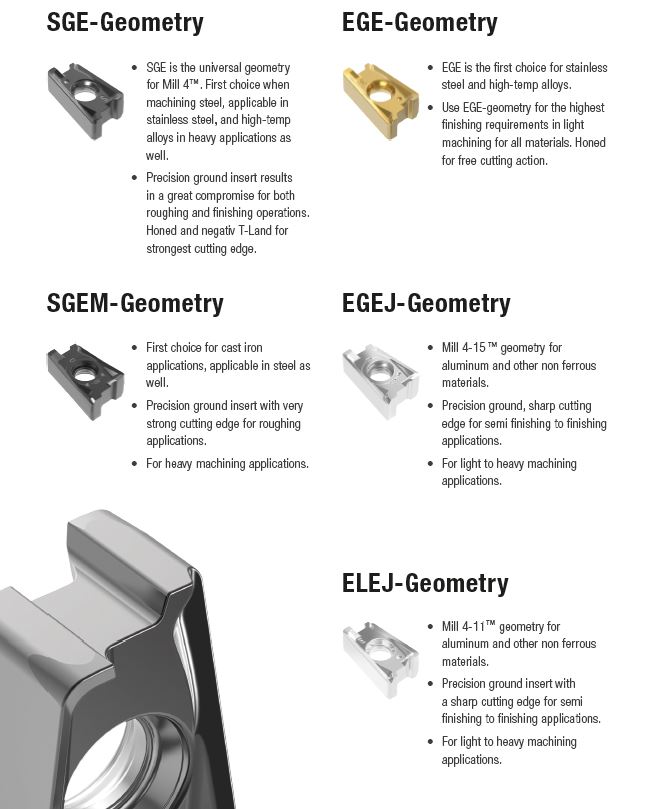

The Mill 4 ™ Series is specially engineered to achieve excellent performance in regards to surface quality as well as higher metal removal rates in shoulder milling applications. Its unique design allows you to apply the tool in multiple passes (step down) with outstanding results from roughing to finishing operations. Mill 4™ is applicable in a wide range of work piece materials: steel, cast iron, stainless steel, non-ferrous materials, and high-temp alloys

The Mill 4-11™ with up to a 0.433" depth of cut, is the solution for low horsepower consumption while the Mill 4-15™ with up to a 0.590" depth of cut, is the solution for more powerful machines. Features for both series include: superior wall and surface finish capabilities, double-sided strong insert with 4 cutting edges, screw-on, end mill, and shell mill cutters with internal coolant, and uneven pocket spacing.

A challenge with step down applications is, that most tools leave tool marks with every pass they take. Resulting in unsatisfactory or low quality wall finishes while requiring another finishing pass at the very end of the process. Applying Mill 4 ™ delivers pristine wall finishes, and eliminates that finishing pass with an additional tool. That saves you time, and reduces your production cost. Insert features include: double-sided strong inserts with 4 cutting edges, a comprehensive offering to cover all applications in all material groups, high positive geometries for lower cutting forces, and “stepless” solutions for multiple-pass operations.

Please visit MSCDirect.com for the full selection of Mill 4™ cutters and insert geometries.

Mill 4™ has solutions for materials such as; steel, cast iron,stainless steel, non-ferrous materials, and high-temp alloys.

Applying Mill 4™ delivers pristine wall finishes, and eliminates that finishing pass which reduces time and cost.

Kennametal brings together materials science, technical expertise, innovation and superior customer service to help the world fly, drive, power and build. Our tools, materials and wear-resistant solutions enable customers to run longer, cut faster and machine with greater precision across various industries from aerospace and defense, general engineering and transportation, to earthworks and energy. We don’t just make products, we deliver solutions.