Video Transcript

CLAY PLATT: When we talk about tooling, there's high performance tools. There’s not so high-performance tools, but we needed something in that middle range that's going to perform really well; be extremely cost-effective and versatile. At the same time, you know where customers can change parts, not tools… where they can change other material groups, not tools.

Narrator: This video is brought to you by Kennametal. Transforming how everyday life is built. If you're looking for real-world insights, tips from leading industry experts, and the latest trends in products and technology, you've come to the right place. From MSC Industrial Supply, this is Tooling Up.

TONI NEARY: Hi everyone, and welcome to Tooling Up. I'm your host, Toni Neary, and I'm so glad that you've joined us here today. Before we begin, let's go ahead and take a minute to click those “Like” and “Subscribe” buttons so you never miss an episode from MSC and our amazing industry partners. Today, I'm excited to welcome Clay Platt. He's a regional product manager for solid and indexable milling at Kennametal.

Clay brings more than 20 years of hands-on manufacturing experience to the table. From running machines and programming on the shop floor to now helping customers solve real-world machining challenges every single day. Clay, welcome to Tooling Up. It's so great to have you here with us today.

CLAY PLATT: Thank you so much, Tony. It is my pleasure to be here, and I'm super excited today to really dive into some milling operations and talk shop with you guys.

TONI NEARY: So, Clay, your experience with running machines and managing operations gives you a very different perspective when you're helping customers choose the right tooling solutions, right?

CLAY PLATT: Yeah. Most definitely. You know, there are many challenges in the workplace and in the manufacturing environment. And when you can see it from a different lens, not just in the shop, but outside the shop, it really brings a little bit of a different perspective to the table.

TONI NEARY: And let's talk a little bit about some of the different components that can really impact that cycle time, like changeover scrap efficiency. How does your experience on the shop floor help with some of those different areas? Really understanding that.

CLAY PLATT: When you're talking about helping customers out, and you're looking at cycle times, you're looking at efficiency, you're looking at scrap rates, you're evaluating all these different things that they're challenged with. You know, there are many things that you could dig into. And in many cases nowadays we just don't have the level of experience in the shop floor as we did in previous years.

The highly experienced people have retired, and the people coming into the positions are not as experienced as they were previously. So the tooling needs to be a little bit more forgiving. You know, there needs to be some versatility within operations for these customers and that's one of the things that we've been focused on is delivering those tools that are capable of doing a wide range of operations.

TONI NEARY: And I think that brings us to our main topic for today, the GOmill™ PRO. Can you describe a little about the problems that this tool will help solve on the shop floor?

CLAY PLATT: You know, we've got extremely high-performance tools capable of running extreme lengths of time in extreme conditions. Well, those come with extreme price tags. And you know that it's great when you've got a customer that's running thousands and thousands of one component that we can precisely dial in a tool. But that's not the case for all customers.

There are so many customers out there today that has that very low experience level, that has a high turnover rate on components and different products. And the tool that we're going to talk about today really can achieve a lot of those challenges with changing materials and changing parts a lot. That's the big focus with it, and it's versatility in operations.

TONI NEARY: And I think you just hit on a key component, and that is changeovers. So I love the fact that when we're talking about the new GOmill™ PRO, we're keeping this tool in the spindle longer. You can run across multiple materials. You can handle a variety of operations. And I think looking at that, that allows us to look at some of the key features.

So let's talk about what the features are that make this just so amazing for the customers that are using this.

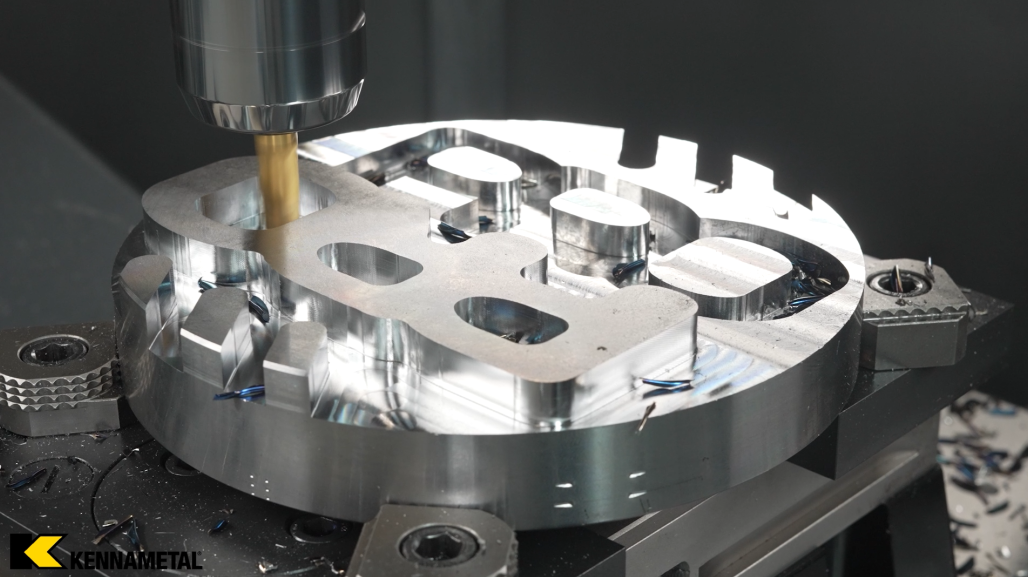

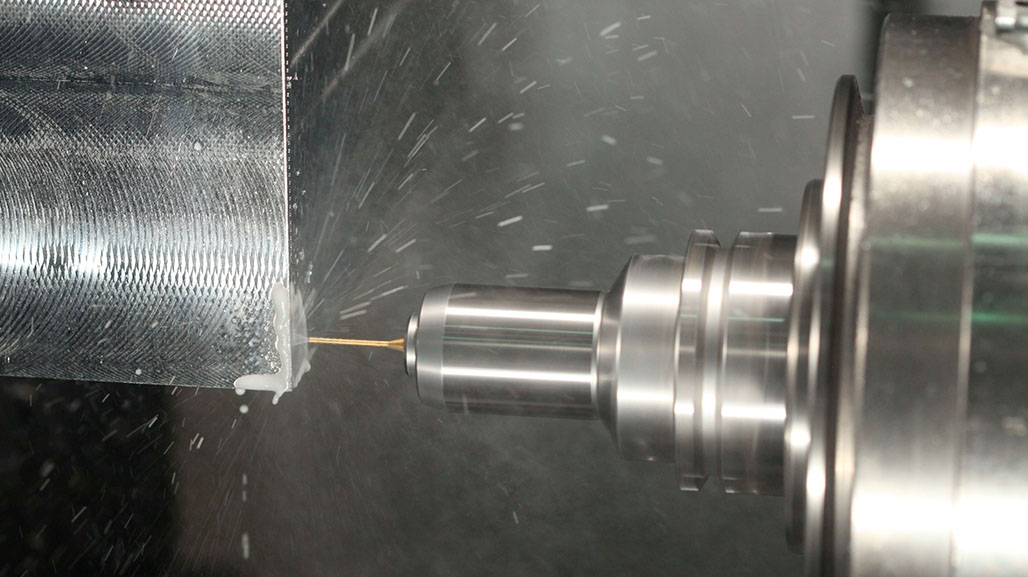

CLAY PLATT: Absolutely. So the GOmill™ PRO is a 4 flute design. We've got a wide offering within that geometry, you know, the asymmetric and the divided flutes as well as the variable helix, you know, both of those working hand in hand to dampen those harmonics and create a much, much more versatile tool and deliver, you know, much better surface finishes and operations.

Not only those key features, but as well as the tapered core design, a tapered core design really strengthens that tool and makes it versatile across many operations.

TONI NEARY: And I love the fact that all of those features working together are going to make this a forgiving yet predictable tool. I feel like we could use a little bit more of that in the world right now, and predictability is huge when you're trying to keep things running smoothly on the shop floor. So we know this is stable, we know it's reliable.

Now let's talk about how it can perform across different operations, including different materials.

CLAY PLATT: When we talk about tooling, there's high performance tools. There's not so high performance tools. But we needed something in that middle range that's going to perform really well. They’re extremely cost-effective and versatile. At the same time, you know, where customers can change parts, not tools where they can change over material groups, not tools. Even through the coating technology that we have, our multi-layer secret sauce that we've got, our substrate that we use, that is also the backbone of the tool.

All of those key features really stimulate the capabilities of the tool and operations. You may be running steels, you may be running stainless, you may be running aluminum. You may even filter into some hot temp alloys. With the way the multi-layer coating is designed and you know, in conjunction with all the other configurations, it is designed to achieve those demanding operations across all of those material groups.

TONI NEARY: And I feel like coding is only part of the equation. So let's talk about chip evacuation and how important that is for the process as well.

CLAY PLATT: We've done a lot of testing, extensive testing, and really dial that design into where it works efficiently across all operations, whether you're full slotting, pocketing, side milling, ramping, you name it. That's where our focus is.

TONI NEARY: So whether you're switching materials or switching jobs, you’re really just not starting from scratch every single time.

CLAY PLATT: You're exactly right, Toni, yes.

TONI NEARY: And we've talked a lot about versatility and performance, but at the end of the day, cost matters. So how does the GOmill™ PRO help shops reduce costs when it comes to changeovers and downtime?

CLAY PLATT: Most shops that have a high changeover rate, where they're running short quantities of parts and components, it's hard for them to justify a tool that's at a premium price. That's a high-performance tool. So we wanted a tool that was capable of staying in the machine longer, running across multiple material groups, being that extremely versatile tool while also being able to perform at an efficient enough level to make customers competitive in their workspace.

TONI NEARY: Clay, we covered a lot today. From shop floor realities to versatility, stability and cost efficiency. As we close things out, what's the message that you want manufacturers to take away about the GOmill™ PRO?

CLAY PLATT: One takeaway that we want everyone to understand it's all about simplifying machining. You know, we want customers not worrying about changing tools all the time. We want them to worry about changing those parts and keeping their operations going.

TONI NEARY: And that is such an important point, because when tooling works the way it's supposed to, it removes friction from the entire process. Clay, thank you so much for joining us today and sharing your perspective and your passion.

CLAY PLATT: Absolutely. Thank you.

TONI NEARY: It was so great spending time with Clay today. And if you want to learn more about the GOmill™ PRO and how it can simplify everyday machining, connect with your MSC metalworking specialist or go to www.mscdirect.com/products/gomillpro. Thanks so much for watching, and we'll see you next time on Tooling Up.

Narrator: Want more insights and ideas to improve the efficiency and productivity of your operations? Check out the Tooling Up video playlist to hear tips that can take your company to the next level, and subscribe to our channel so you won't miss out.