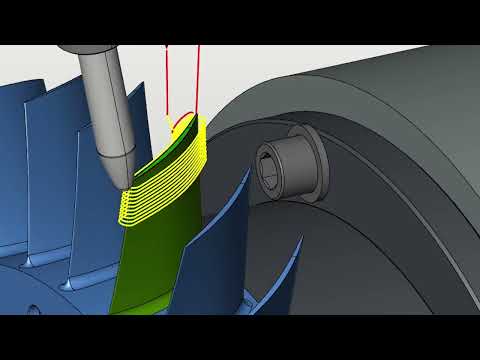

VIDEO: Challenges of Machining the Blisk in Aerospace Industry

Seco Tools can help you optimize blisk manufacturing with better tools and strategies.

Seco Tools can help you optimize blisk manufacturing with better tools and strategies.

To access content to help you optimize your machining applications of aerospace components like the blisk, visit SECO Tools' website.

Previously Featured on Seco Tools' YouTube channel.

A highly competitive industry, aerospace manufacturing needs to reduce costs through production efficiencies as new materials and product designs further complicate the machining process. Aircraft fuel efficiency demands heat-resistant materials for engine blisks that can survive hotter fuel burns in the hot section of the engine and lightweight materials in the cold section. Because of this high temperature, super alloys are used for the blisk. This, in turn, increases the complexity of manufacture. As a tool supplier with deep industry expertise, Seco can deliver a full turnkey solution to help manufacturers optimize their CNC machining strategies from programming recommendations to custom 3D printed tools and efficient approaches. These advantages help manufacturers use fewer tools and processes in their quest to succeed. For a complete solution to efficient, high-quality blisk production, visit secotools.com.

Seco Tools is your complete metalworking solutions provider offering cutting-edge, precision tools for indexable milling, solid milling, hole making, turning, threading, grooving and more. We’re proud to make for makers, invent for inventors, and partner with pioneers. In short - if the right tool for the job exists, we’ll deliver it. If it doesn’t, we’ll create it.