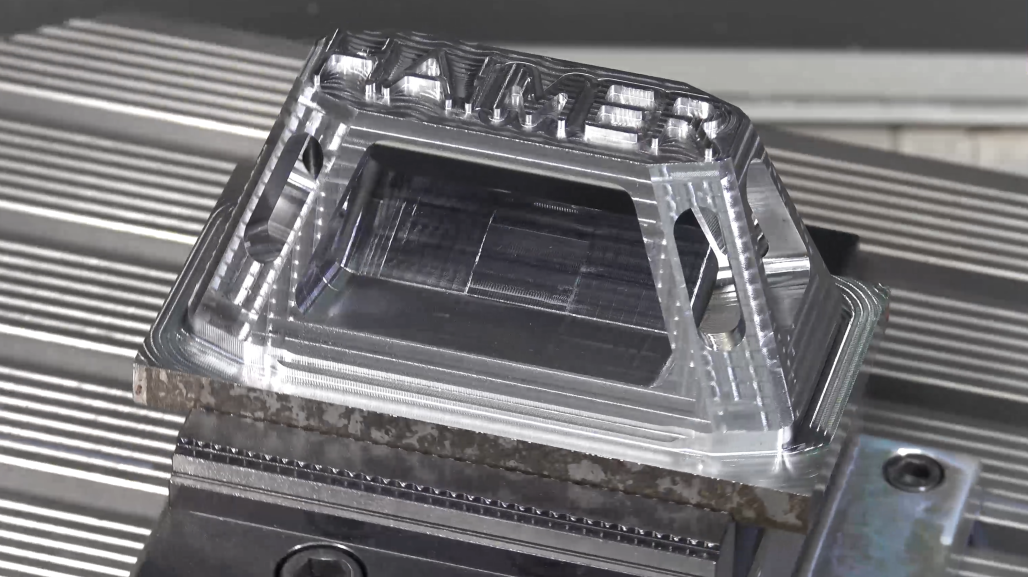

VIDEO: Series 51 T Carb: Trochoidal Milling at its Finest

In a Case Study on the Series 51 T-Carb conducted by KYOCERA SGS, an aerospace customer saw a total savings of almost 40%.

In a Case Study on the Series 51 T-Carb conducted by KYOCERA SGS, an aerospace customer saw a total savings of almost 40%.

In a Case Study on the Series 51 T-Carb conducted by KYOCERA SGS Precision Tools, an aerospace customer saw a total savings of almost 40%. The goals of this study were to significantly reduce job cost through reduced cycle time, increasing MRR and reducing total machining time. KYOCERA approached this job with a 6 flute T-Carb end mill, which excels at high-speed machining. Specifically, trochoidal and peel milling, the T-Carb's 6 flute design with eccentric relief provides strength and supreme chip control at high speeds, and with surprising finish results.

The T-Carb was able to capacitate significantly higher speed and feed rates. Thus, the material removal rates for the T-Carb were almost double the MRR of the competitor’s tool. The total machining hours were almost cut in half, reducing the total machining cost by over $36,000. Download a PDF of the Case Study here to learn more.

Watch the Series 51 T-Carb in action in the short video above (music and captions only, no transcript).

Previously Featured on KYOCERA's YouTube channel.

You can find the Series 51 T-Carb corner radius end mill or the square end mill on MSCDirect.com.

KYOCERA Precision Tools is a world-class manufacturer of indexable tooling solutions. At KYOCERA, we’re passionate about revolutionary cutting tool technology. We design and develop advanced indexable cutting tools that not only meet but exceed quality expectations, all while delivering the cost-efficiency that today’s metalworking professionals need to stay competitive in a variety of industries including, aerospace, automotive, medical, small parts, and mold & die