There are many benefits to using a thread former over a traditional cutting tap such as no chip formation, no miscutting, improved surfaces and the high strength of formed thread. The new versatile high-performance TC420 Supreme thread former builds upon these advantages and features a new substrate and a new polygon geometry that provides better forming behavior, less friction, and longer tool life. In addition, its polished surface yields a better surface finish than is achieved with thread cutting.

This combination of features allows the new Walter TC420 Supreme thread former to reach higher tool life by producing up to 30% lower torque with higher cutting speeds. There are numerous variants in the TC420 Supreme product range, such as various coolant configurations, thread tolerance, chamfer forms and overall lengths. The new thread former can be used universally since it is ideally suited for most ISO material groups. Applications include 3.5 x DN with grooves/internal cooling, and 3.0 x DN without grooves/ internal coolant.

For a Complete Offering of Walter Tools visit MSCDirect.com.

Brought to you by Walter Tools

Walter is a global leader in precision metalworking solutions, delivering high-performance tools for milling, turning, drilling, and threading. Serving aerospace, automotive, energy, and general engineering industries, we combine innovation with expertise to maximize productivity. More than a tool provider, Walter is a trusted partner, offering cutting-edge machining solutions that drive efficiency, quality, and performance in manufacturing worldwide.

Related Articles

VIDEO: HOW TO Implement Grinding Solutions with Automation

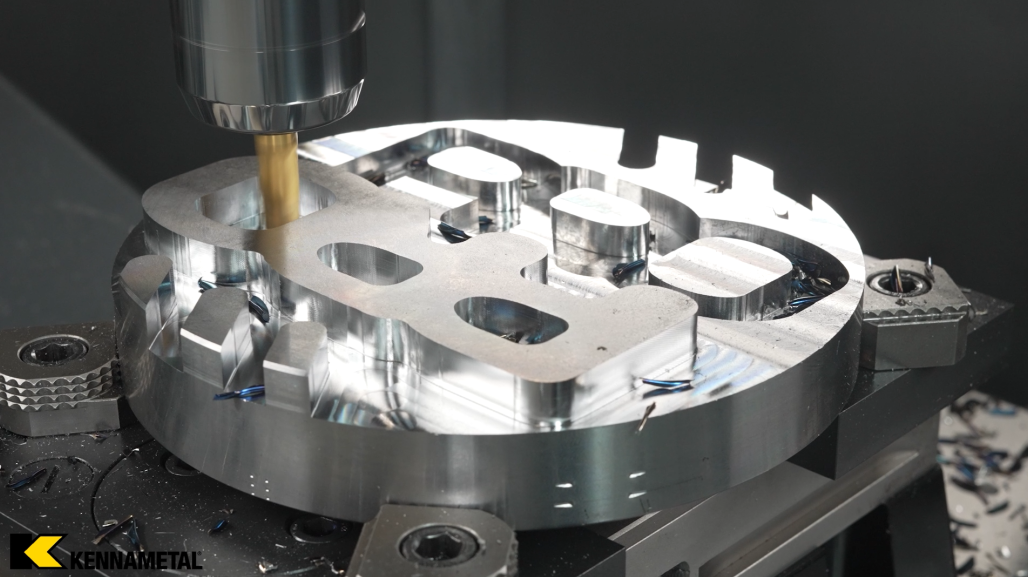

TOOLING UP: Simplifying Milling Operations with Kennametal’s GOmill™ PRO

Tech Tip: A Hydraulic Chuck Quick Guide

Microfiber Tech: MFT PRO Gloves Pair Comfort and Performance